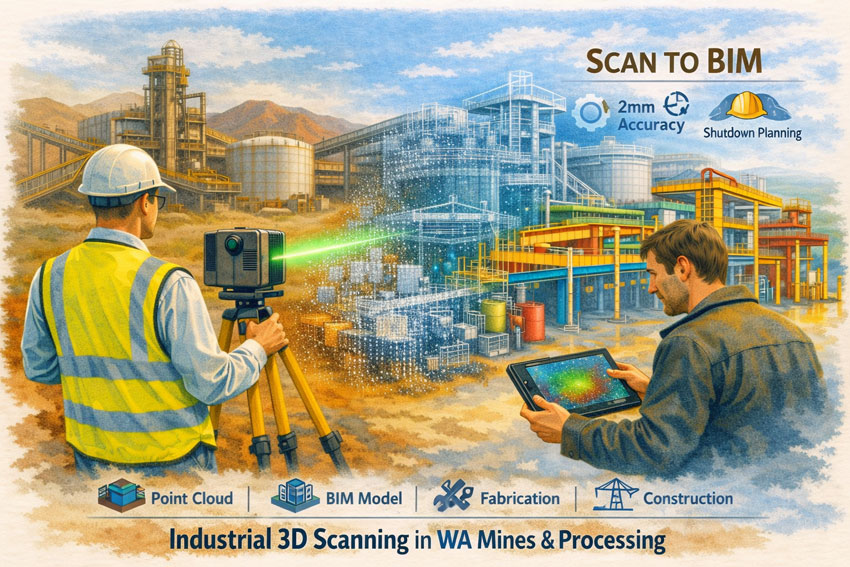

Industrial 3D Scanning in WA Mines & Processing | Scan-to-BIM

Building Engineering Certainty in Brownfield Environments

Western Australia’s mining and mineral processing sector operates some of the most complex industrial assets in the world. Aging infrastructure, continuous production demands, and aggressive expansion schedules mean that every engineering decision must be based on accurate, reliable information. Industrial 3D Scanning in WA Mines & Processing has become the foundation for achieving this certainty—providing precise digital representations of plants, structures, and equipment before a single drawing is issued.

The Backbone of Modern Mine Engineering

A laser scan is not simply a survey tool; it is the backbone of the entire project lifecycle. The quality of the initial scan determines the ease and accuracy of every task that follows—layout design, clash detection, fabrication, and construction. If the backbone is broken, even simple tasks become difficult. Poor capture leads to rework, fabrication errors, and costly shutdown delays.

Industrial 3D scanning captures millions of measured points across conveyors, tanks, structural steel, pipe racks, and mechanical equipment with millimetre accuracy. For WA mine sites where access is restricted and downtime is expensive, this technology removes guesswork and replaces assumptions with verified data.

From Point Cloud to BIM Deliverables

The true value of scanning lies in what is delivered after capture. For mines and processing facilities, typical outputs include:

- Engineering-grade point clouds for AutoCAD, Revit, and plant design platforms

- Scan-to-BIM models of structures, pipework, and mechanical systems

- Fabrication-ready DXF, STEP, or Parasolid files

- Navisworks meshes for stakeholder review and constructability planning

- As-built verification for shutdown and tie-in works

These deliverables allow engineering teams to design remotely, plan upgrades with confidence, and eliminate the need for repeated site visits across the vast distances of Western Australia.

Protecting the Project Team

Industrial projects are often pressured by schedules and budgets. High-quality 3D scanning protects the entire delivery team—project managers, engineers, designers, and fabricators—by providing an objective source of truth. When design decisions are based on measured reality rather than tape measures and sketches, disputes reduce and collaboration improves.

For brownfield WA sites with decades of undocumented modifications, scanning becomes the neutral reference that aligns contractors, owners, and operators around the same dataset.

Applications Across WA Mines & Processing

Industrial 3D Scanning in WA Mines & Processing supports a wide range of activities:

- Shutdown planning and tie-in verification

- Conveyor and chute upgrades

- Tank and structural remediation

- Pipe spool prefabrication

- Access platform and maintenance improvements

- Expansion of crushing and screening circuits

- Safety and egress compliance reviews

Whether in the Pilbara iron ore operations, Goldfields processing plants, or nickel and lithium facilities, scanning reduces risk in some of Australia’s harshest and most remote environments.

Remote Doesn’t Mean Isolated

Western Australian mine sites can feel isolated, yet digital capture connects them directly to engineering teams anywhere in Australia. A single field visit can provide enough data for months of detailed design work. Teams can “walk the plant” virtually, measure clearances, and develop solutions without repeated flights or shutdown interruptions.

An Engineer-Led Approach

Effective scan programs must be led by engineers who understand how the data will be used. Capture strategies, target placement, and accuracy tolerances are defined around the BIM deliverables, not around the scanner. This ensures that the final models support fabrication, not just visualisation.

Industrial 3D Scanning in WA Mines & Processing is no longer optional—it is the starting point for safe, efficient, and predictable project delivery. When the backbone is strong, every downstream task becomes easier.

If your operation is planning upgrades, shutdowns, or expansions, begin with a measured digital foundation and let the data drive the outcome.