SolidWorks Modelling, Drafting & Engineering Services

Precision CAD for Mining, Manufacturing, Construction & Industrial Projects Across Australia

SolidWorks is at the heart of modern engineering design — and at Hamilton By Design, it forms the foundation of our entire digital engineering workflow. We use SolidWorks to transform field data, LiDAR scans, sketches and engineering intent into accurate, fabrication-ready models and drawings that fit first time on site.

From mining wash plants and conveyors to custom machinery, structural steel and plant upgrades, our SolidWorks capability supports projects across heavy industry, manufacturing, power stations and construction sectors throughout Australia.

Why SolidWorks?

SolidWorks is one of the world’s leading parametric 3D CAD platforms. It allows designers, drafters, engineers and fabricators to work collaboratively inside a powerful modelling environment that supports precision, automation and engineering validation.

Using SolidWorks, we can deliver:

- Fully parametric 3D models

- Intelligent assemblies with clear structure

- Accurate fabrication, machining and general arrangement drawings

- DXFs for laser/plasma cutting

- BOMs and part numbering systems

- Clash checking and motion studies

- Engineering simulation (FEA) when required

Whether you’re designing new equipment or upgrading existing infrastructure, SolidWorks ensures accuracy, repeatability and seamless integration with real-world fabrication workflows.

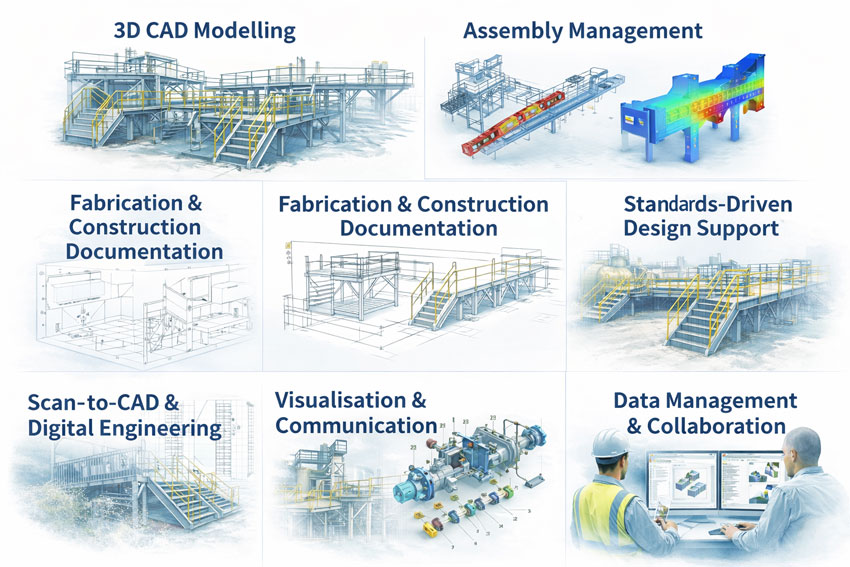

Our SolidWorks Services

Hamilton By Design offers a complete suite of SolidWorks engineering and drafting services, including:

3D Parametric Modelling

- Mechanical components and assemblies

- Structural steel frames, walkways and supports

- Chutes, tanks, hoppers, piping and mechanical equipment

- Models built from LiDAR point clouds, sketches or legacy drawings

- Configurable models for product variations

2D Drafting & Detailed Drawing Production

- Fabrication drawings with weld symbols, material specs and tolerances

- Machining drawings with hole tables, GD&T and section details

- Assembly drawings with exploded views and Bills of Materials

- General arrangement (GA) drawings for installation and site coordination

As-Built Modelling & Revision Updates

- Laser scan–based as-built modelling for accuracy within ±1–3 mm

- Updating outdated or incomplete drawing sets

- Reverse-engineering legacy equipment and parts

- Incorporating site mark-ups and supervisor feedback

Design for Manufacture & Installation (DFM/DFI)

- Models and drawings structured around efficient workshop fabrication

- Logical transport splits and lifting points (as directed by engineers)

- Identifying potential installation conflicts before fabrication

- Seamless coordination with boilermakers, machinists and installers

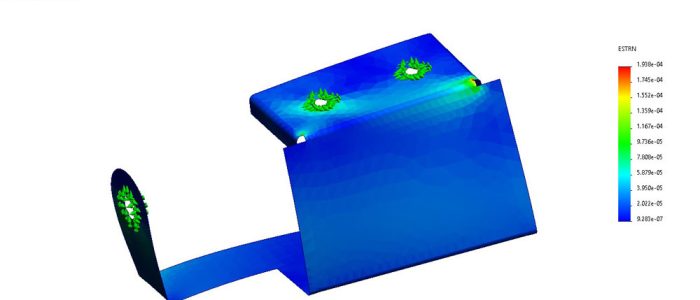

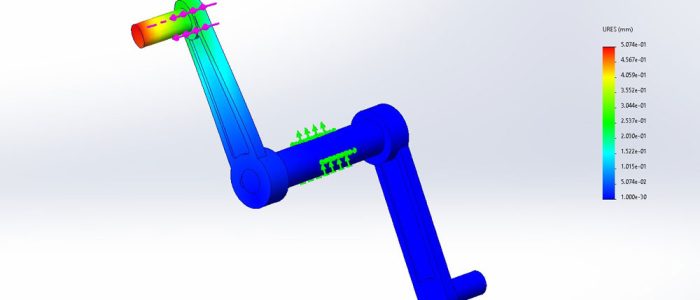

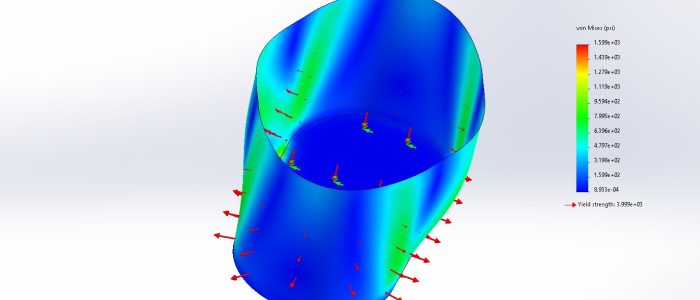

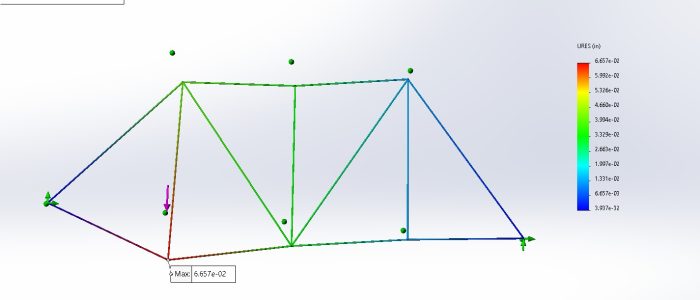

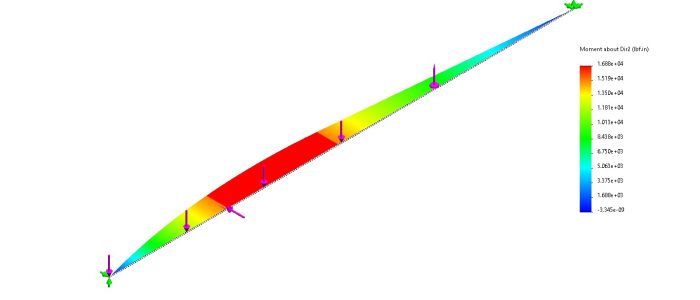

Simulation & Engineering Validation (FEA)

When required for engineering refinement, we can integrate:

- Static FEA

- Weld analysis

- Deflection studies

- Bolt and connection checks

- Material optimisation

Industries We Support With SolidWorks

Our SolidWorks services support clients across:

- Coal wash plants (CHPP), mining and materials handling

- Hard rock processing plants

- Steel fabrication and manufacturing

- Power stations and energy infrastructure

- Industrial construction and commercial buildings

- Data centres and modular upgrades

- Mechanical equipment design, jigs and fixtures

If it’s made, machined, fabricated or installed — SolidWorks helps bring it to life.

SolidWorks + 3D Laser Scanning = Engineering-Grade Accuracy

One of Hamilton By Design’s strongest capabilities is combining SolidWorks with high-accuracy LiDAR scanning.

This workflow ensures that every model and drawing is aligned with true site conditions — drastically reducing rework, clashes and shutdown costs.

Our workflow:

- LiDAR Scan → Point cloud capture

- Registration & Cleanup → Precise as-built data

- SolidWorks Modelling → Fit-for-purpose geometry built to site reality

- FAB Drawings → Ready for plasma cutting, machining and workshop fabrication

- Installation Confidence → Fit-first-time outcomes

This workflow is ideal for brownfield upgrades, shutdown preparation, chute replacements, platforms and mechanical modifications.

Why Choose Hamilton By Design for SolidWorks Work?

We bring the perfect blend of engineering experience, drafting expertise and practical understanding of industrial environments.

You benefit from:

- Deep experience in mining, industrial and fabrication projects

- Models and drawings that are clean, organised and easy for your team to work with

- A site-aware mindset — considering lifting, access, installation and maintenance

- Fast turnaround when deadlines, shutdowns and fabrication schedules matter

- Flexible engagement — project-by-project, hourly or ongoing drafting support

- Direct communication with a mechanical engineer, not just a CAD operator

Our aim is not just to draw — but to partner with you to deliver better engineering outcomes.

Engage SolidWorks Specialists Today

Whether you need additional drafting support, a full engineering drawing package, or a complete as-built model from a laser scan, Hamilton By Design can help.

Let’s discuss your project requirements

We’ll tailor a SolidWorks package that matches your scope, timeline and fabrication needs.