Engineering-Grade 3D LiDAR Scanning for Industrial & Mining Assets

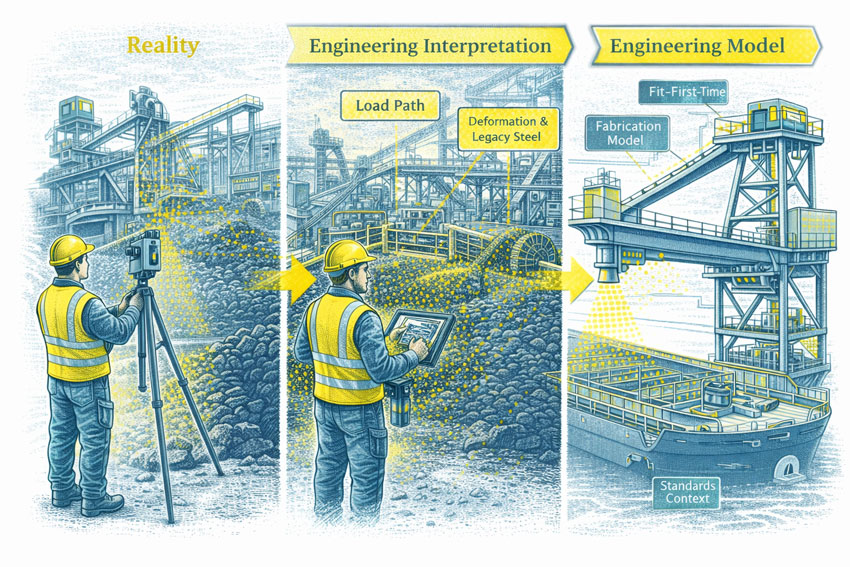

Industrial and mining facilities rarely match their original drawings. Over years of operation, shutdown upgrades, temporary works, and undocumented modifications, the true as-built condition of assets becomes uncertain.

Hamilton By Design provides engineering-grade 3D LiDAR scanning for industrial and mining environments — delivering engineered as-built data that can be confidently used for mechanical design, structural verification, compliance assessment, and fabrication-ready documentation.

This is not scanning for visualisation.

This is scanning for engineering decisions.

Why Conventional 3D Scanning Fails in Industrial Environments

Many organisations already have laser scans, yet still experience:

- Fabrication that does not fit on site

- Structural clashes discovered during installation

- Rework during shutdowns

- Safety and compliance gaps

- Models that look accurate but cannot be engineered

These failures occur because most scans are captured without engineering context.

Common issues include:

- No understanding of load paths or structural behaviour

- No allowance for deformation, wear, or misalignment

- Survey-grade outputs delivered without design intent

- Point clouds handed over with no accountability for engineering use

In industrial environments, data without interpretation introduces risk.

What “Engineering-Grade” LiDAR Scanning Actually Means

Engineering-grade LiDAR scanning integrates engineering judgement into every stage of the capture-to-model workflow.

Accuracy Aligned to Engineering Use

- Local accuracy suitable for mechanical interfaces

- Controlled registration focused on critical geometry

- Tolerances aligned with fabrication and installation requirements

Engineering Interpretation of the Point Cloud

- Identification of structural versus non-structural elements

- Recognition of deformation, wear, and legacy modifications

- Assessment of which geometry can be relied upon for design

Design-Ready Outputs

- SolidWorks-based 3D CAD models

- Interfaces defined for new works and retrofits

- Geometry suitable for detailing, load checks, and verification

A point cloud alone does not provide engineering certainty.

Engineering interpretation does.

Standards, Compliance, and Risk Context

Industrial assets are governed by Australian Standards, safety legislation, and duty-of-care obligations. Accurate as-built information is often the starting point for demonstrating compliance and reducing risk.

Engineering-grade LiDAR scanning is commonly used to support:

- Conveyor safety and guarding compliance

- Bulk solids handling and load assessment

- Structural steel verification

- Mechanical fit-up and clearance checks

- Plant modifications and upgrades

Our Engineer-Led LiDAR Scanning Workflow

Our workflow is deliberately engineer-led, ensuring accountability from site capture through to fabrication-ready outputs.

1. Engineering-Driven Site Capture

Scanning is planned around:

- Known and suspected modification scopes

- Interfaces critical to new works

- Areas of structural or compliance risk

- Access and shutdown constraints

2. Controlled Point-Cloud Processing

- Registration verified against engineering requirements

- Validation of critical geometry

- Noise reduction aligned to modelling intent

3. Engineering Interpretation

- Identification of true load-bearing elements

- Recognition of temporary and legacy works

- Assessment of deformation and alignment

4. 3D CAD Modelling (SolidWorks)

- As-built geometry modelled to engineering tolerances

- Interfaces defined for fabrication and installation

- Models structured for downstream design and detailing

5. Engineering Verification (Where Required)

- Mechanical and structural checks

- Load paths and operational constraints reviewed

- Design validation prior to fabrication

6. Fabrication-Ready Deliverables

- General arrangement drawings

- Detailed fabrication drawings

- Bills of materials and installation references

This single-source workflow removes the hand-offs that typically lead to rework.

Typical Assets We Scan and Model

Engineering-grade LiDAR scanning is routinely applied to:

- Conveyors and transfer stations

- Hoppers, bins, and silos

- Chutes and wear liners

- Pipe racks and services

- Platforms, walkways, and mezzanines

- Structural steel in brownfield facilities

- Processing plant and bulk materials systems

These assets are rarely square, level, or unchanged — which is precisely why scanning must be engineered.

Brownfield and Live-Site Environments

LiDAR scanning is particularly valuable where:

- Assets must remain operational

- Access is restricted or hazardous

- Drawings are incomplete or unreliable

- Traditional measurement introduces safety risk

Non-contact scanning allows accurate capture without interfering with operations, while still delivering engineering-usable data.

Supporting “Fit-First-Time” Outcomes

The real cost of poor as-built information is rarely the scan itself. It is reflected in:

- Fabrication rework

- Installation delays

- Extended shutdowns

- Safety exposure

- Loss of confidence in engineering documentation

Engineering-grade scanning reduces these risks by ensuring:

- Interfaces are verified before fabrication

- Design assumptions are checked

- Construction teams receive buildable information

This is how digital capture translates into physical certainty.

Where This Service Is Delivered

Hamilton By Design delivers engineering-grade LiDAR scanning across metropolitan, regional, and remote industrial locations throughout Australia.

A dedicated Sydney-focused delivery page builds on this engineering framework to address the specific challenges of brownfield, compliance-driven assets in NSW.

Why Hamilton By Design

Clients engage Hamilton By Design because we provide:

- Engineer-led scanning and modelling

- Mechanical and structural engineering integration

- Single-source accountability

- No scanning-only hand-offs

- Deliverables designed for fabrication and construction

We do not sell point clouds.

We deliver engineering-usable truth.

Our clients