AS 3774 Hopper Design Loads – Bulk Solids Handling Engineering

In bulk materials handling, the ultimate operational goal is steady-state production — consistent throughput, predictable equipment loading, and minimal process disruption.

Hoppers play a critical role in achieving this outcome. However, the benefits they provide come with structural and load complexities that must be correctly understood and engineered. This is where AS 3774 – Loads on Bulk Solids Containers becomes essential.

Why Do You Want a Hopper in Your Process?

In simple terms, having a hopper in your system allows you to maintain constant production.

Most industrial plants aim to operate in a steady-state condition, where material flow remains as uniform as possible. In reality, upstream and downstream equipment rarely operate at the same rate, and bulk materials themselves are inherently variable.

A hopper acts as a buffer.

By decoupling one part of the process from another, a hopper allows fluctuations in feed rate, equipment performance, or material behaviour to be absorbed without immediately impacting the rest of the plant.

As a general principle:

The more hoppers you have in the right locations, the more steady-state your operation becomes.

Buffering Variability and Increasing Capacity

Hoppers contribute to steady-state operation in two key ways:

1. Stabilising Flow

Hoppers smooth out:

- Surging feed rates

- Short interruptions upstream

- Variations in material size and moisture

This allows downstream equipment—such as feeders, conveyors, screens, and mills—to operate closer to their design point.

2. Providing Extra Capacity

Hoppers also introduce process capacitance.

This additional capacity:

- Buys time during plant upsets

- Reduces nuisance trips and shutdowns

- Improves overall plant availability

From a production perspective, hoppers are one of the most effective tools available for improving consistency and utilisation.

The Engineering Reality: Hoppers Are Load-Critical Structures

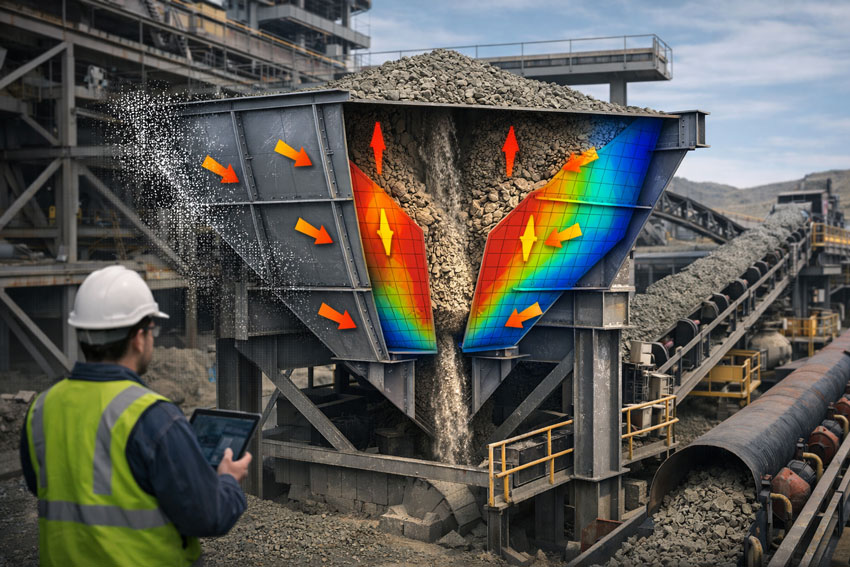

While hoppers improve process stability, they also introduce complex structural load cases.

Bulk solids do not behave like liquids or static dead loads. As material is filled, stored, and discharged, the loads acting on hopper walls and supporting steelwork change significantly.

AS 3774 exists to address this exact problem.

The standard defines load cases associated with:

- Filling conditions

- Static storage

- Flow and discharge

- Eccentric and asymmetric draw-down

These load cases are often higher and more uneven than designers expect, particularly during discharge.

What Happens When AS 3774 Is Not Properly Applied?

When hopper loads are underestimated or simplified, common outcomes include:

- Buckled or permanently deformed hopper walls

- Cracking at welds and transitions

- Fatigue issues in supporting structures

- Excessive vibration during operation

- Premature failure during throughput increases

Ironically, the very hoppers intended to stabilise production can become the source of downtime if not correctly designed or assessed.

Geometry Matters: Why As-Built Conditions Are Critical

AS 3774 calculations are highly sensitive to geometry.

In brownfield plants, hopper drawings are often:

- Out of date

- Incomplete

- No longer representative of site conditions

Modifications, liner additions, repairs, and wear can all change how loads are transferred into the structure.

This is why engineering-grade as-built data is critical when assessing existing hoppers.

Engineering-Led AS 3774 Assessment

At Hamilton By Design, hopper assessments are approached as a combined process and structural problem, not just a compliance exercise.

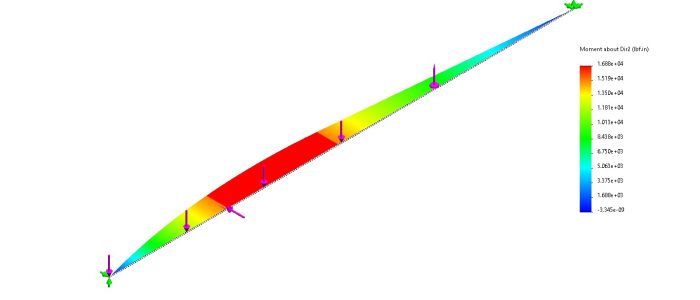

Our workflow typically integrates:

- High-accuracy 3D LiDAR scanning to capture true geometry

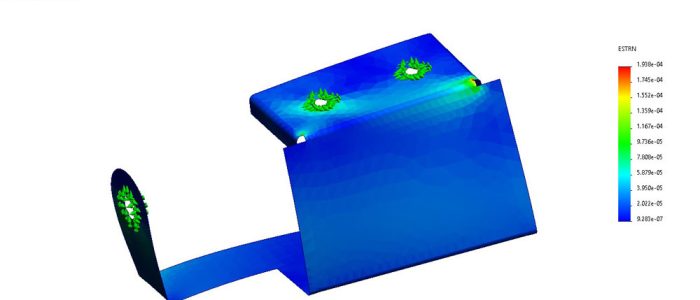

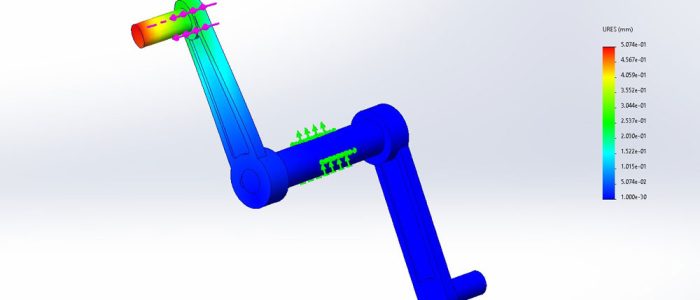

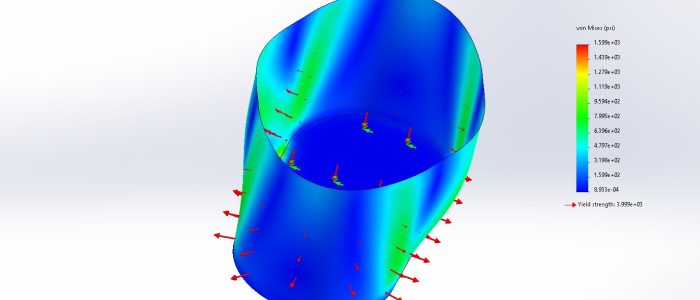

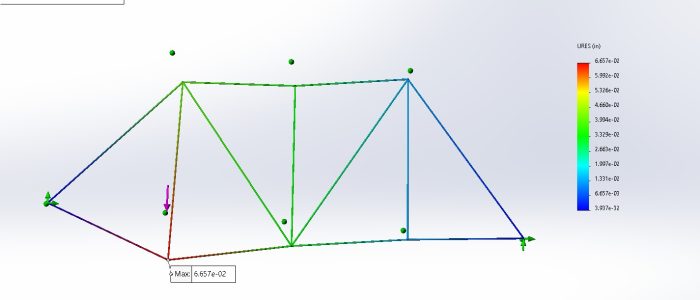

- SolidWorks 3D modelling of hoppers and support steelwork

- Structural FEA with AS 3774 load cases applied

- Targeted strengthening or upgrade design where required

This allows clients to:

- Increase throughput with confidence

- Extend asset life

- Avoid unnecessary replacement

- Maintain steady-state operation safely

Bringing It All Together

Hoppers are fundamental to stable, high-availability bulk materials processing.

They:

- Enable steady-state production

- Buffer variability

- Provide valuable process capacity

But they also:

- Introduce complex, non-intuitive loads

- Demand careful application of AS 3774

- Require accurate geometry and engineering verification

When hopper design and assessment are done correctly, they support production.

When they are not, they quietly become one of the highest structural risks in the plant.

Our clients: