Clear, reliable engineering decisions

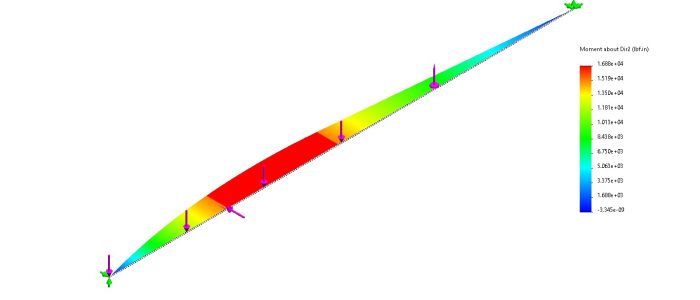

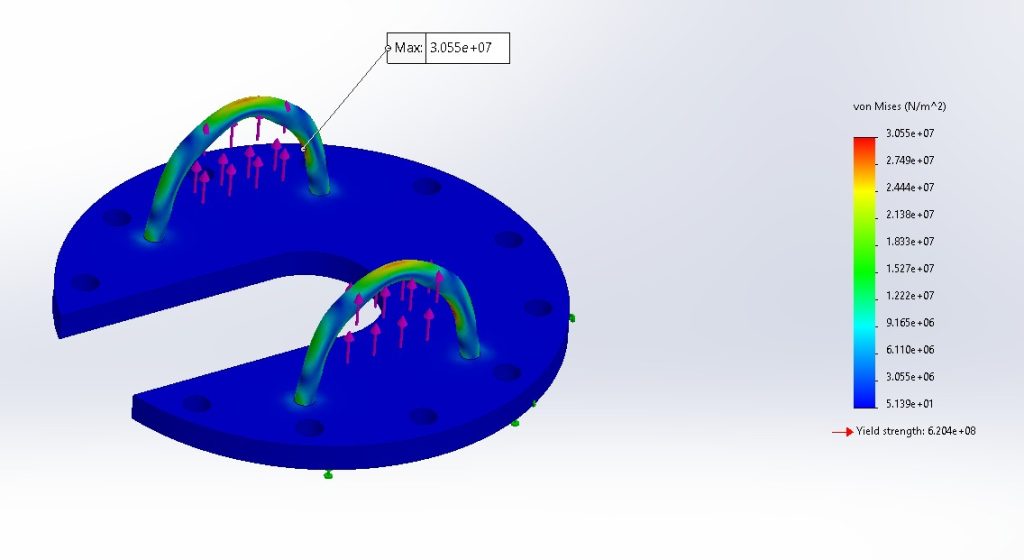

Hamilton by Design provides end-to-end Finite Element Analysis (FEA) to help you validate designs, reduce risk, and move faster. We handle quick checks through to complex non-linear and dynamic studies—explained in plain English and backed by solid engineering.

What we do (not limited to)

Core FEA

- Linear static stress for parts and assemblies

- Time-based motion / kinematic analysis

Advanced (Simulation Professional level)

- Fatigue (constant & variable amplitude)

- Modal (resonant frequency) and buckling

- Steady-state and transient thermal

- Drop-test and impact

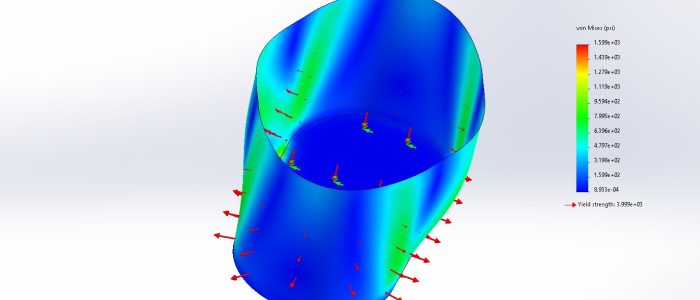

- Pressure vessel assessment

- Topology optimization

- Submodeling and load-case management

Specialist (Simulation Premium level)

- Non-linear statics: plasticity, hyperelastic materials, large deflection, complex contact

- Non-linear dynamics: rate-dependent behaviour, contact events

- Linear dynamics: time history, harmonic response, random vibration, response spectrum

- Composite laminate analysis: ply-by-ply results, Tsai-Hill / Tsai-Wu failure

Typical outputs

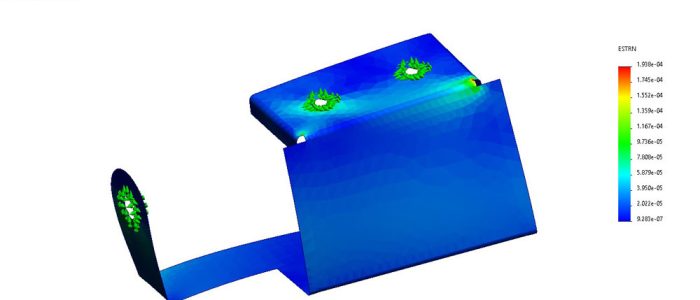

- Stress/strain maps (von Mises, principal, safety factors)

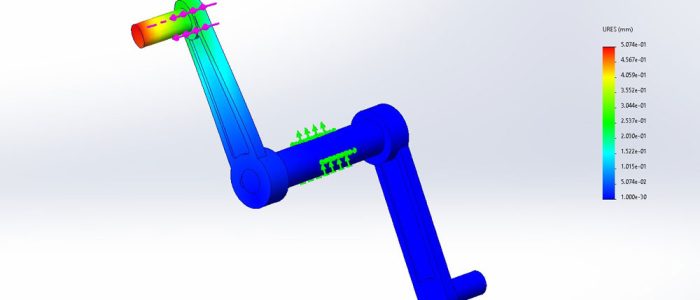

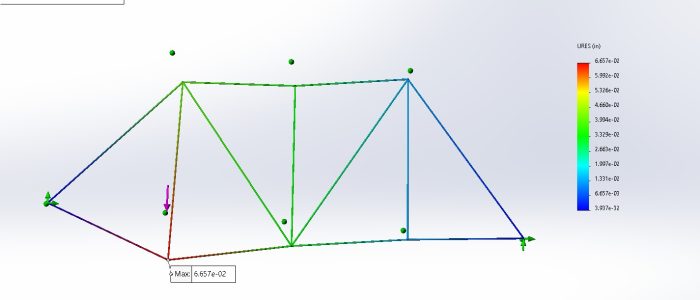

- Deflection and stiffness results (linear and large-deflection)

- Modes and vibration responses (harmonic, random)

- Fatigue life and damage accumulation

- Thermal distributions and heat-flow

- Clear pass/fail against your acceptance criteria

How we work

- Scope & assumptions – Define loads, constraints, materials, and success criteria.

- Model prep & meshing – Clean geometry, set contact strategy, plan mesh convergence.

- Simulation & calibration – Run studies with sensitivity checks; refine as needed.

- Validation & reporting – Concise report, native files, and practical design recommendations.

Who we support

Industrial equipment • Aerospace • Defense & robotics • Marine & offshore • Energy & thermal systems • Consumer products

Toolchain

SOLIDWORKS® 3D CAD Premium with SOLIDWORKS Simulation Professional & Simulation Premium add-ins.

Engagement options

- NDA-friendly

- Fixed-price or time & materials

- Rapid turnaround available

Get in touch

Email: sales@hamiltonbydesign.com.au

Location: Australia (AEST)

Mechanical Engineering | Structural Engineering

Mechanical Drafting | Structural Drafting

3D Laser Scanning | 3D CAD Modelling | 3D Scanning