Fabrication Integrated Modelling (FIM): Why It’s the Future for Local Fabricators

Why It Is the Future for Local Fabricators

The fabrication industry is undergoing a fundamental transformation. Increasing project complexity, tighter tolerances, compressed schedules, labour shortages, and rising material costs are placing unprecedented pressure on fabricators — particularly local workshops operating in competitive markets. At the same time, clients are demanding greater certainty: certainty of fit, certainty of schedule, and certainty of cost.

Traditional fabrication workflows, built around 2D drawings and manual interpretation, are no longer sufficient to meet these expectations. They rely heavily on experience, assumptions, and rework — all of which introduce risk. In this environment, Fabrication Integrated Modelling (FIM) is emerging not as a luxury, but as a necessity.

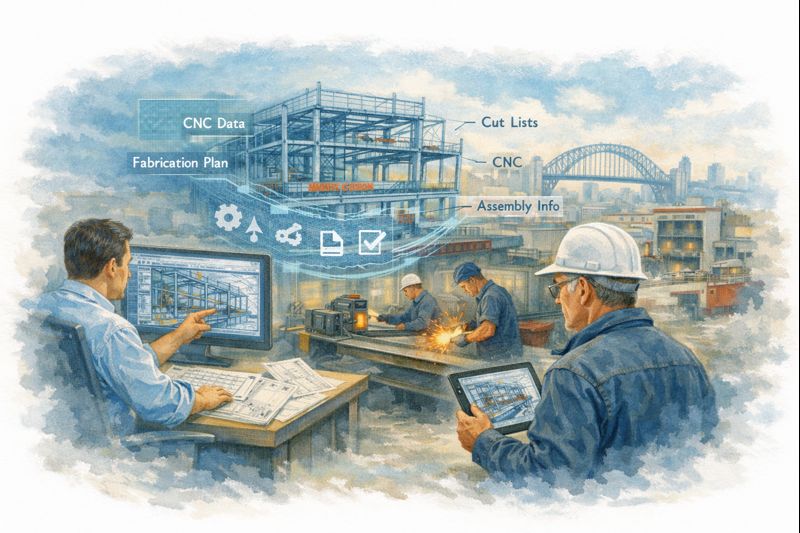

FIM represents a shift from drawing-based fabrication to model-driven fabrication, where a single, coordinated digital model governs design intent, fabrication detailing, procurement, machining, assembly, and installation. For local fabricators, this shift offers a path to higher productivity, improved margins, and long-term relevance in an evolving industry.

What Is Fabrication Integrated Modelling (FIM)?

Fabrication Integrated Modelling is a methodology where the fabrication model becomes the primary source of truth across the entire project lifecycle. Instead of treating design, drafting, fabrication, and installation as disconnected stages, FIM integrates them into a continuous digital workflow.

In an FIM environment:

- Engineering intent is embedded directly into the model

- Fabrication constraints are considered from the outset

- Quantities, tolerances, and interfaces are defined digitally

- Fabrication data flows directly to machines and shop documentation

- Installation sequencing is validated before material is cut

The model is not merely a visual aid — it is a fully informed digital prototype of the fabricated asset.

From Drawings to Data: A Fundamental Shift

Historically, fabrication has relied on 2D drawings as the primary communication tool. These drawings require interpretation by drafters, trades, and supervisors, each introducing assumptions based on experience and context. While this approach has worked for decades, it becomes increasingly fragile as projects grow more complex.

Fabrication Integrated Modelling replaces interpretation with explicit data. Hole locations, weld preparations, connection details, clearances, and tolerances are all defined within the model. This reduces ambiguity and ensures that everyone — from estimator to machine operator — is working from the same information.

The result is a dramatic reduction in errors, clarifications, and rework.

Why FIM Is Gaining Momentum Now

Several industry pressures are accelerating the adoption of FIM:

- Increasing complexity of industrial and infrastructure projects

- Reduced tolerance for errors during shutdowns and brownfield upgrades

- Labour shortages and loss of experienced trades

- Higher expectations for schedule and cost certainty

- Growing integration of CNC and automated fabrication equipment

FIM addresses these challenges by improving coordination, predictability, and efficiency at the source — before fabrication begins.

Key Benefits of Fabrication Integrated Modelling

Reduced Errors and Rework

Rework is one of the most significant drains on fabrication profitability. Errors discovered on the workshop floor or during installation often result in cascading impacts: delays, additional labour, material waste, and strained relationships with clients.

By resolving interfaces, clashes, and tolerances digitally, FIM enables fabricators to identify and eliminate issues before steel is cut. Assemblies are tested virtually, connections are validated, and fit-up risks are significantly reduced.

This proactive approach shifts problem-solving upstream, where changes are faster, cheaper, and less disruptive.

Improved Fabrication Efficiency and Throughput

Fabrication speed is not achieved by rushing work — it is achieved by removing uncertainty. FIM provides clarity on what needs to be fabricated, in what order, and to what tolerance.

Benefits include:

- Clear fabrication sequencing

- Reduced downtime waiting for clarifications

- Better planning of labour and machine utilisation

- More predictable workshop flow

Local fabricators using FIM often report smoother operations, fewer interruptions, and a higher percentage of “right-first-time” components.

Better Use of Skilled Labour

Skilled trades are becoming harder to find and retain. Fabrication Integrated Modelling helps maximise the value of skilled workers by giving them better information, not more guesswork.

Fitters receive assemblies that align as expected. Welders focus on quality rather than correcting geometry. Supervisors make decisions based on accurate model data rather than assumptions. Apprentices gain clarity and confidence by working from model-based instructions.

Rather than replacing experience, FIM captures and amplifies it.

Seamless Integration with CNC and Fabrication Equipment

One of the strongest advantages of FIM is its ability to connect directly with modern fabrication equipment. The same model used for coordination and verification can generate machine-ready data, including:

- NC files for beam lines and plate processors

- Cut lists and nesting data

- Part numbers and assembly marks

- Machining references

This eliminates duplication of effort and reduces the risk of transcription errors. It also shortens the time between design approval and fabrication start, improving responsiveness to project changes.

Competitive Advantage for Local Fabricators

Local fabricators often compete with offshore suppliers on price alone — a contest that is difficult to win. FIM allows local workshops to compete on value rather than cost.

Key differentiators enabled by FIM include:

- Faster response to changes

- Higher confidence in fit-up for complex or brownfield sites

- Reduced installation risk

- Stronger collaboration with engineers and constructors

When site conditions change — as they inevitably do — local fabricators using FIM can adapt quickly, update models, and deliver revised components without significant disruption. This agility is a powerful advantage over remote fabrication alternatives.

FIM in Brownfield and Upgrade Projects

Brownfield projects present some of the greatest challenges in fabrication. Existing assets rarely match legacy drawings, and tolerances are often tight. Discovering misalignment during installation can result in costly delays and extended shutdowns.

Fabrication Integrated Modelling, often combined with accurate site capture, allows fabricators to design and fabricate components that align with actual site conditions rather than assumptions.

This approach reduces:

- On-site modifications

- Temporary works

- Installation delays

- Safety risks associated with forced fit-ups

For local fabricators servicing industrial plants and operational facilities, FIM is rapidly becoming an expected capability.

Financial Benefits: Protecting Margins, Not Just Schedules

While FIM is often associated with speed and accuracy, its most important benefit may be margin protection.

Model-based workflows enable:

- More accurate pricing through reliable quantities

- Reduced contingency allowances

- Predictable labour and machine hours

- Lower material waste

- Fewer disputes and variations

By increasing certainty, FIM allows fabricators to price work confidently rather than defensively. Over time, this leads to healthier margins and more sustainable operations.

Earlier Engagement and Better Project Outcomes

Fabricators who adopt FIM often find themselves involved earlier in projects. Engineers and asset owners increasingly recognise the value of fabrication input during design development.

Early collaboration enables:

- Design for manufacture and assembly

- Smarter connection strategies

- Reduced installation complexity

- Improved safety outcomes

This shifts the fabricator’s role from reactive supplier to active project partner, strengthening relationships and improving project outcomes for all parties.

Overcoming Barriers to Adoption

Adopting Fabrication Integrated Modelling requires investment — not only in software and systems, but in people and processes. Common challenges include:

- Training requirements

- Changes to established workflows

- Initial productivity adjustments

- Cultural resistance to new methods

Successful fabricators address these challenges incrementally. They start with pilot projects, focus on repeatable wins, and work closely with engineering and modelling partners to build capability over time.

The risk of maintaining outdated workflows is increasingly greater than the risk of change.

The Future of Fabrication: Integrated Digital Ecosystems

FIM is not the final destination — it is the foundation for a more connected fabrication industry. As digital maturity increases, fabrication models will increasingly link to:

- Digital twins

- Quality assurance records

- Traceability and compliance systems

- Asset management platforms

- Automated inspection and verification

In this future, the fabrication model becomes a long-term asset, supporting not only construction but operation and maintenance.

Why Fabrication Integrated Modelling Is the Future for Local Fabricators

Local fabrication is not disappearing — it is evolving. Workshops that continue to rely solely on 2D drawings and manual processes will face increasing pressure from cost, risk, and competition. Those that embrace Fabrication Integrated Modelling will position themselves for long-term success.

By adopting FIM, local fabricators can:

- Deliver higher quality with greater confidence

- Reduce rework and wasted effort

- Protect margins in competitive markets

- Strengthen relationships with engineers and clients

- Build resilient, future-ready businesses

Fabrication Integrated Modelling is not about replacing trades or experience. It is about supporting them with better information, clearer intent, and integrated workflows.

For local fabricators willing to invest in capability and collaboration, FIM is not just the future — it is the pathway to remaining relevant, competitive, and profitable in an increasingly digital industry.