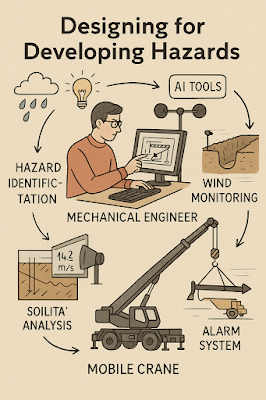

Designing for Developing Hazards

Crane accidents are among the most visible reminders of the risks inherent in construction. The collapse of a crane at a data centre site in Derrimut, Melbourne, brought attention once again to the vulnerability of temporary lifting structures. While formal investigations are still underway, and no conclusions should be drawn prematurely, the event provides a valuable opportunity for reflection within the engineering community.

This article considers the collapse not as an isolated failure but as a case study in hazard identification. In particular, it highlights how mechanical engineers must adapt from a static, design-phase view of risk to a dynamic, real-time approach to hazard monitoring. Wind, soil stability, and load conditions are well-known hazards. But with modern tools — including LiDAR scanning for obstacle detection — engineers can move toward a future where developing hazards are continuously tracked, anticipated, and controlled.

From Hazard Identification to Live Hazard Monitoring

Hazard identification has traditionally been a design-phase process: engineers anticipate risks, apply safety factors, and create conservative margins. This remains essential. Yet the Derrimut collapse illustrates the limits of a static model in a dynamic environment.

Cranes are exposed to evolving hazards:

- Wind gusts that change minute by minute.

- Soil stability that shifts with rainfall, excavation, or groundwater.

- Obstacles such as power lines or nearby structures, which can create cascading risks if struck.

- Load dynamics, including swinging or sudden movement.

What is needed is a transition from hazard identification to hazard monitoring: a continuous loop where design assumptions are validated against real-time data, and where developing risks are detected before they become failures.

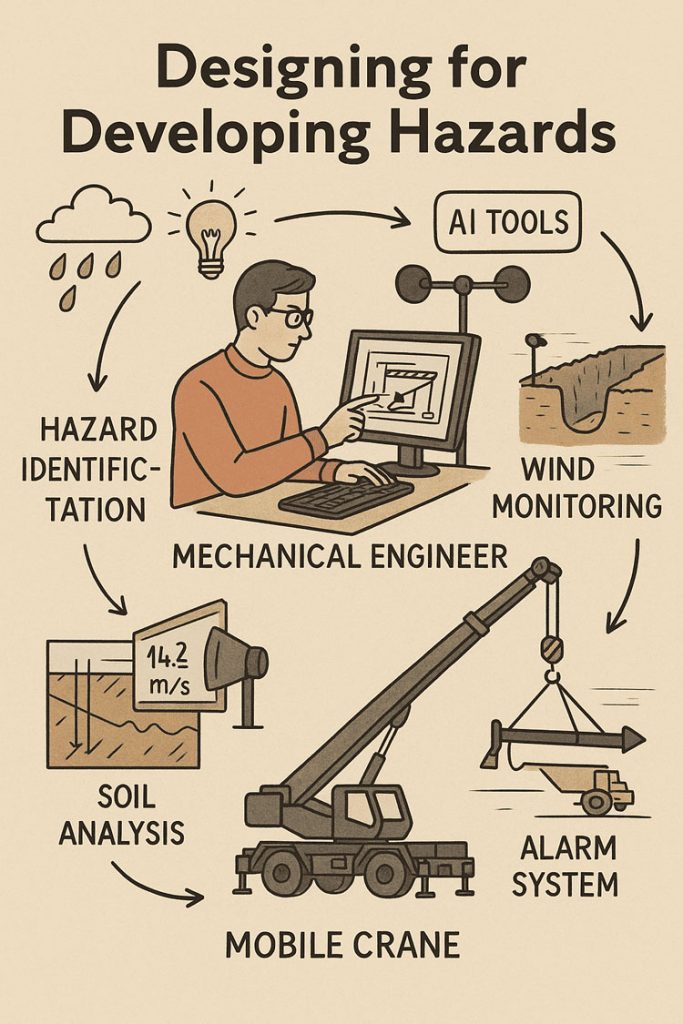

Wind Hazards: Predicting the Unpredictable

Wind is a leading cause of crane collapses. Engineers know the mathematics: pressure rises with the square of velocity. A 50 km/h gust exerts twice the force of a 35 km/h breeze.

Most cranes today are fitted with anemometers and alarms, but these are often basic: a single reading at a single point, with alarms sounding when preset thresholds are exceeded. This approach can miss:

- Local gust variability along a long jib.

- Interaction with crane orientation (wind hitting the broadside is more critical than aligned wind).

- Forecasted conditions that could deteriorate within minutes.

Next-generation wind monitoring could include:

- Multi-point sensor arrays on cranes.

- Integration with Bureau of Meteorology gust forecasts.

- AI models predicting when risk thresholds will be exceeded, not just reporting when they are crossed.

- Automatic crane repositioning to minimise wind exposure.

This transforms alarms from reactive to predictive — the difference between warning after a hazard is present and anticipating before it materialises.

Soil Hazards: Stability Under Load

Ground conditions are another silent but critical hazard. Outriggers may impose hundreds of kilonewtons on pads, meaning even small soil weaknesses can lead to tilting or overturning.

Engineering practice already includes soil investigations: boreholes, CPT, SPT, and FEA models. But these tests capture conditions before installation, not necessarily during operation. Soil strength can change due to rainfall, groundwater shifts, or nearby excavation.

Live soil monitoring can be achieved with:

- Load cells under mats to track ground reactions.

- Settlement gauges to detect tilt.

- Piezometers for pore pressure during rain events.

- Integrated warnings when ground resistance trends downward.

This approach acknowledges soil as a living hazard that changes daily.

LiDAR and Obstacle Detection: Power Lines and Proximity Hazards

One striking feature of the Derrimut collapse was the crane’s boom striking power lines. Contact with utilities is a recurrent hazard in crane operations worldwide. While operators are trained to maintain exclusion zones, in practice visibility, fatigue, or unexpected boom movement can still lead to contact.

LiDAR scanning offers a solution.

- How it works: LiDAR (Light Detection and Ranging) emits laser pulses to map surroundings in 3D with centimetre accuracy. Mounted on a crane, it can create a live digital map of nearby obstacles.

- Application in cranes:

- Detecting and mapping power lines, buildings, or scaffolding in the lift path.

- Setting proximity alarms when a boom, hook, or load approaches a defined clearance.

- Combining with wind data to predict if gusts could push the load into restricted zones.

In aviation, LiDAR and radar-based systems are standard for obstacle detection. In construction, adoption is patchy. Yet the technology exists, is cost-effective, and could dramatically reduce risks of contact with hazards like live power lines.

LiDAR’s strength lies not only in static mapping but in detecting movement — for example, when a suspended load begins to swing toward a power line due to a gust. This is a quintessential developing hazard, one that static design could never fully capture.

Integrated Hazard Dashboards

Wind, soil, and LiDAR obstacle detection all provide valuable data. But their true power lies in integration. Imagine a crane operator’s cabin equipped with a single dashboard displaying:

- Wind speeds and gust forecasts, colour-coded for risk.

- Soil reaction forces under each outrigger, with alerts if settlement is trending.

- LiDAR mapping of nearby structures and power lines, with real-time clearance zones.

- Predictive risk models showing probability of instability or contact over the next 30 minutes.

This integration mirrors aviation’s cockpit: multiple inputs fused into actionable guidance. For cranes, such systems could shift the operator’s role from reactive decision-maker to proactive risk manager.

AI as a Predictive Partner

Artificial Intelligence has a natural role in hazard monitoring:

- Sensor fusion: combining wind, soil, and LiDAR inputs into coherent risk profiles.

- Prediction: learning from past crane incidents to forecast when risks are likely to escalate.

- Decision support: providing operators with clear options (“safe to continue lift for 20 minutes” / “halt operations — clearance margin < 1m”).

The challenge is balance. AI should not replace human oversight, but augment it. Over-reliance could create new vulnerabilities if operators become complacent. The design challenge is to build AI into systems that support human judgment rather than substitute for it.

Ethics and Engineering Responsibility

The Derrimut collapse underscores the ethical responsibility of mechanical engineers. Hazard identification is not just a design requirement; it is a matter of public safety. The profession has a duty to anticipate, detect, and control risks wherever possible.

The tools now exist to monitor developing hazards — wind sensors, soil gauges, LiDAR scanners, and AI dashboards. If lives and infrastructure can be protected through wider adoption of these tools, then the question becomes one of responsibility: should they be optional, or mandatory?

Open Questions for the Future

- Would integrated live monitoring have reduced the risks at Derrimut?

- Should all cranes be fitted with LiDAR obstacle detection as standard?

- Do we already have enough technology, but lack regulation and enforcement?

- What role should AI play in balancing predictive insight with operator autonomy?

The Derrimut incident remains under investigation. No conclusions can be drawn about its specific cause until findings are published. Yet as a case study, it illustrates the broader point that hazards in crane operations are dynamic. Wind, soil, obstacles, and loads evolve minute by minute.

Mechanical engineers have the tools — wind sensors, soil monitors, LiDAR scanners, integrated dashboards, and AI — to detect these developing hazards. The challenge is to move from a culture of static design assumptions to one of continuous hazard monitoring.

The ultimate professional question is this: If aviation can integrate multiple systems to monitor and predict hazards, why can’t construction do the same for cranes? And if we can, how soon will we accept the ethical responsibility to make it standard?

References and Further Reading

- ISO 4301 / AS 1418 — Crane standards covering stability and wind.

- ISO 12480-1:2003 — Safe use of cranes; includes environmental hazard monitoring.

- WorkSafe Victoria Guidance Notes — Crane safety management.

- Holický & Retief (2017) — Probabilistic treatment of wind action in structural design.

- Nguyen et al. (2020) — Real-time monitoring of crane foundation response under variable soil conditions.

- Liebherr LICCON — Example of integrated load and geometry monitoring.

- FAA LLWAS — Aviation’s real-time wind shear alert system, model for construction.

- Recent research in LiDAR obstacle detection (e.g., IEEE Transactions on Intelligent Transportation Systems) — showing LiDAR’s potential in complex environments.

Our clients: