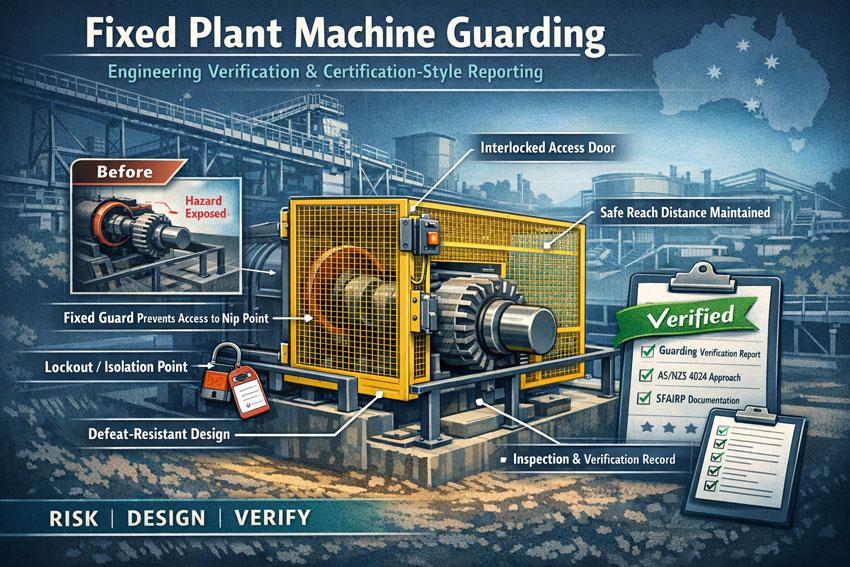

In industrial and mining environments, machine guarding is not a “nice to have” — it’s a critical engineering control that protects people, prevents downtime, and demonstrates compliance with Australian WHS expectations.

Hamilton By Design Co. provides engineering-led design consulting and certification-style verification for fixed plant machine guarding, including new guarding systems, upgrades, and retrofit solutions for existing equipment.

Our focus is simple: protect workers, support safe production, and provide clear, defensible engineering documentation.

What We Mean by “Guarding Certification”

In Australia, machine guarding is not typically certified under a single universal “product stamp.” Instead, machine guarding is assessed and verified through:

- engineering design and risk-based safeguarding

- alignment to recognised standards and good practice

- site verification, inspection, and documentation that supports WHS duties

When we certify a guarding design, we provide an engineering verification that the guarding system has been assessed against Australian safety expectations and provides risk reduction so far as reasonably practicable (SFAIRP) for the intended use.

Fixed Plant Machine Guarding Services

We support fixed plant guarding across mining, processing, manufacturing, infrastructure and heavy industry, including:

Guarding Design & Retrofit Engineering

- Fixed guards, mesh guards and perimeter guarding

- Access prevention and safe maintenance access planning

- Retrofit guarding upgrades for brownfields equipment

- Guard structural design (frames, supports, fixings, corrosion allowance)

Guarding Verification & Certification Reports

- Guard inspections (site verification and measurements)

- Guarding compliance review and gap assessments

- Design verification and risk reduction justification

- Practical recommendations that balance safety and maintainability

Interlocks & Guarding Systems (Design Support)

- Guard-associated interlocking concepts

- Lock-out and isolation integration

- Practical “defeat-resistant” guard design principles

(Where functional safety calculations or specialist electrical control validation is required, we can work alongside your controls team or specialist partners.)

What We Deliver

Each project is documented for clarity and defensibility. Typical deliverables include:

- Guarding risk review (hazards, access points, foreseeable misuse)

- Design drawings / sketches and installation guidance

- Verification checklist (inspection points and acceptance criteria)

- Engineering Verification Report (often used as “certification” evidence)

- Photo record and “as-installed” notes (where applicable)

- Limitations, assumptions, and maintenance requirements

Standards & Compliance Approach

Our methodology is aligned with widely accepted Australian safeguarding practice, including:

- AS/NZS 4024 (Safety of Machinery series)

- Risk-based safeguarding methodology consistent with ISO 12100 principles

- WHS duty expectations for plant and machinery risk control

We don’t just reference standards — we apply them to real conditions on your site: access, maintenance needs, exposure time, and realistic human behaviour around machines.

Who We Work With

We support:

- mine sites and processing plants

- maintenance departments

- project teams (brownfields upgrades and shutdown work)

- workshop supervisors and fabrication teams

- OEMs and equipment suppliers needing Australian verification support

Whether your plant is locally built or imported, the end goal is the same: a safe guarding system that holds up under WHS scrutiny.

Why Hamilton By Design

Hamilton By Design is an engineer-led team that understands operational realities. We design guarding that:

- protects people without creating unsafe workarounds

- supports maintainability and inspection access

- is practical to fabricate and install

- is backed by professional engineering documentation

If you need a guarding solution that is fit-for-purpose and properly verified, we can support your team from assessment to final sign-off.

Typical Use Cases

- Imported machinery requiring Australian guarding verification

- Pre-commissioning guard reviews before handover

- Incident-driven guarding upgrades

- Shutdown retrofit packages and fabrication-ready guard designs

- Periodic plant guarding audits and gap registers

Call to Action

If you need a machine guarding certification-style verification or a complete fixed plant guarding design package, contact the Hamilton By Design team.

Let’s reduce risk, protect your people, and keep your plant operating safely.