Engineering-Led 3D Laser Scanning Services in Sydney

3D scanning in Sydney is no longer just about capturing point clouds — it’s about delivering engineering-grade data that can be trusted for design, verification, fabrication, and construction.

At Hamilton By Design, we provide engineer-led 3D laser scanning and reality capture services across Sydney and NSW, supporting projects where accuracy, accountability, and buildability matter.

Our workflows combine LiDAR scanning, CAD modelling, and engineering judgement, ensuring scan data is not only precise — but fit-for-purpose.

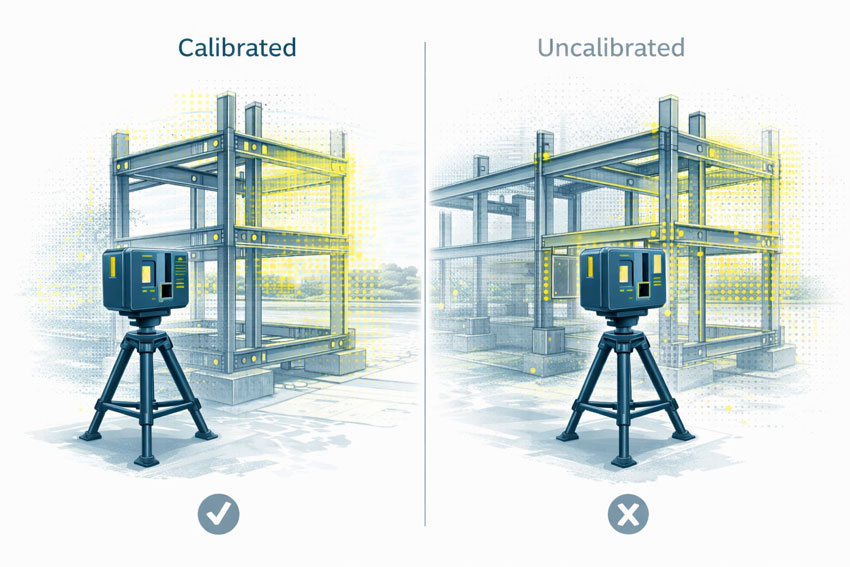

Why Engineering-Grade 3D Scanning Matters

Not all 3D scanning is equal. Many projects fail not because scanning was done — but because it was done without engineering context.

We routinely see issues such as:

- Scan data captured without understanding fabrication tolerances

- Models built directly from point clouds without verification

- Shutdown or site work impacted by poor fit-up

- Drawings that look accurate but fail on site

Our approach closes that gap by ensuring scanning is owned by the engineer, not handed off without accountability.

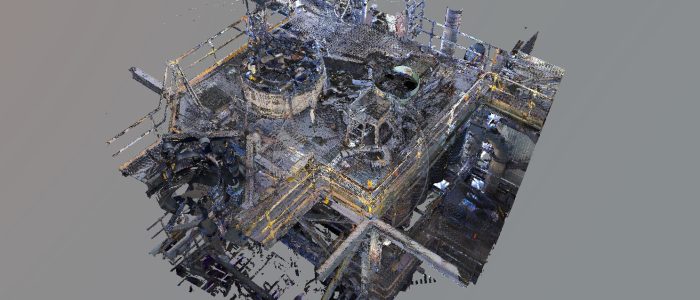

Our 3D Scanning Capabilities in Sydney

We support a wide range of Sydney projects, including:

- Industrial plants & brownfield upgrades

- Mechanical equipment & conveyor systems

- Structural steelwork & platforms

- Buildings, plant rooms & services coordination

- Reverse engineering of legacy assets

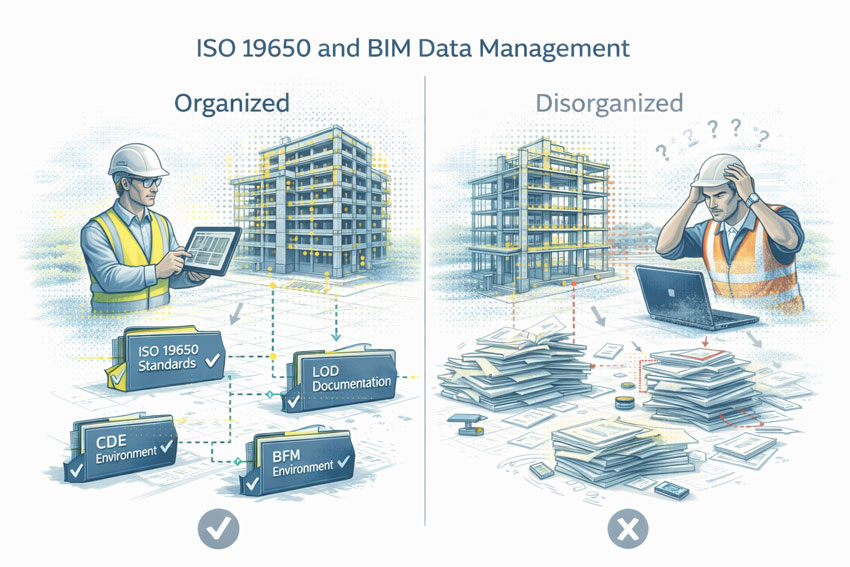

Our deliverables typically include:

- Registered point clouds (E57 / RCP / RCS)

- Verified 3D CAD models (SolidWorks-based)

- Fabrication-ready drawings

- Engineering assumptions & limitations clearly documented

Typical Applications of 3D Scanning in Sydney

3D scanning Sydney services are commonly used for:

- Fit-for-purpose replacement parts

- Shutdown-critical upgrades

- As-built documentation

- Design validation prior to fabrication

- Clash detection and retrofit planning

- Asset verification where drawings no longer reflect reality

We focus on build outcomes, not just digital outputs.

Engineer-Led vs Scan-Only Providers

| Scan-Only Services | Hamilton By Design |

|---|---|

| Technician-captured data | Engineer-led scanning |

| Point cloud delivery only | CAD + engineering intent |

| No ownership of outcomes | Engineering accountability |

| Survey or visual accuracy | Fit-for-fabrication accuracy |

This difference is critical when scanning data is used for steelwork, machinery, or safety-critical assets.

Our clients

Local Sydney Experience, National Capability

While we deliver 3D scanning across Sydney, our experience extends to:

- Mining & heavy industry

- Manufacturing & infrastructure

- Commercial & industrial facilities

This cross-industry experience ensures Sydney projects benefit from lessons learned in high-risk, high-consequence environments.

When Should You Consider 3D Scanning?

You should consider 3D scanning in Sydney if:

- Existing drawings can’t be trusted

- OEM information is outdated or unavailable

- You’ve had fit-up issues before

- A brownfield upgrade has been approved

- Fabrication needs to be right the first time

Work With an Engineer-Led 3D Scanning Partner

Hamilton By Design doesn’t just capture reality — we take responsibility for it.

If you need defensible, engineering-grade 3D scanning in Sydney, backed by CAD modelling and real-world fabrication experience, we can help.

Connect with us by filling out the form below to discuss your 3D scanning requirements in Sydney.