EinScan vs LiDAR Terrestrial Laser Scanners – Choosing the Right Tool for Reality Capture

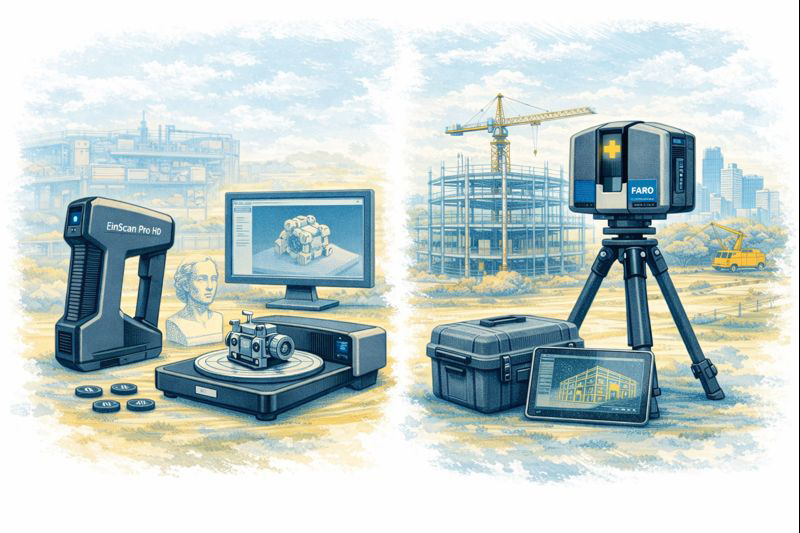

The rapid growth of 3D scanning has given engineers, fabricators and designers access to tools that were once limited to large survey companies. Today you can buy a compact EinScan structured-light scanner for a few thousand dollars or hire a FARO or Leica terrestrial LiDAR scanner capable of mapping an entire processing plant in an afternoon. Both are called “3D scanners,” yet they serve very different purposes. Understanding the difference between EinScan-style scanners and terrestrial LiDAR systems is essential before investing time or money into reality capture.

Two Technologies, Two Different Jobs

EinScan scanners, produced by SHINING 3D, are primarily structured-light or short-range laser scanners. They project patterns of light onto an object and use cameras to interpret how that light deforms across the surface. The result is a dense mesh model of the object—typically exported as STL, OBJ or PLY files. EinScan units are designed for objects you can walk around, such as mechanical parts, castings, plastic housings and small assemblies.

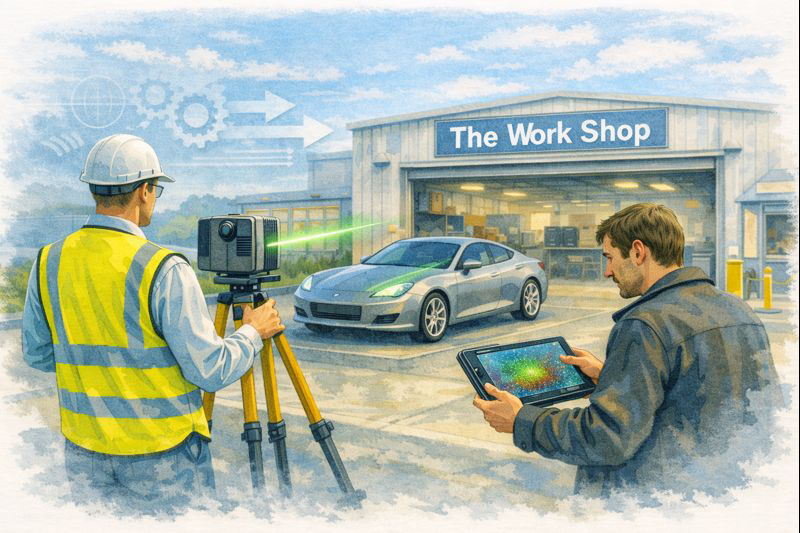

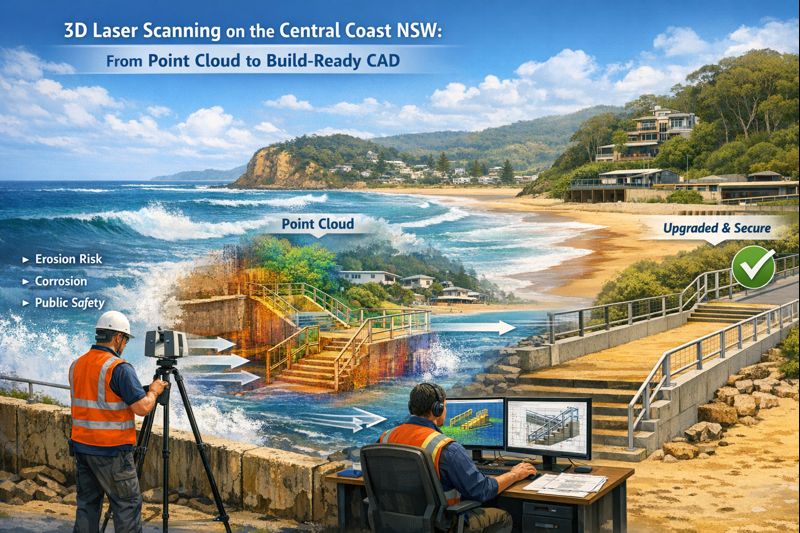

Terrestrial LiDAR scanners such as the FARO Focus, Leica RTC360 or Trimble X-series operate on a completely different principle. These instruments sit on a tripod and fire millions of laser pulses across a 360-degree field, measuring the time it takes for each pulse to return. The output is a georeferenced point cloud containing precise XYZ coordinates for everything the laser can see—buildings, structures, conveyors, tanks, pipework and terrain.

Calling both devices “3D scanners” is like calling a vernier caliper and a total station the same tool. They both measure, but at entirely different scales.

Scale and Range

The first and most obvious difference is working range.

An EinScan handheld unit is comfortable scanning parts from a few centimetres up to perhaps three or four metres. It is ideal for a gearbox housing on a bench or the plastic bumper of a vehicle. Once the object grows larger than a small room, the scanner begins to lose tracking and accuracy.

A terrestrial LiDAR scanner is built for the opposite end of the spectrum. A FARO Focus S-series can capture data from 0.6 metres out to 70 metres or more, mapping entire buildings or industrial sites from a single setup. Multiple scans are then registered together to create a complete digital twin of a facility.

For workshops and machine shops the question becomes simple:

Are you scanning an object, or are you scanning a place?

Objects suit EinScan; places suit LiDAR.

Accuracy and Tolerance Expectations

Manufacturers often quote impressive numbers, but real-world accuracy must be considered.

- EinScan desktop and handheld systems typically achieve 0.05–0.2 mm accuracy on small parts when conditions are ideal.

- Terrestrial LiDAR scanners deliver around ±1 mm to ±3 mm accuracy over distance.

At first glance EinScan appears “more accurate,” but this is only true at short range. A LiDAR scanner maintains consistent accuracy across tens of metres, something structured-light devices simply cannot do.

For precision mechanical components—bearing fits, machined bores, threaded holes—neither technology replaces traditional metrology tools. Scanning excels at capturing shape and context, while micrometers and CMMs remain the authority for tolerance verification.

Type of Data Produced

EinScan produces mesh files made from millions of tiny triangles. These are excellent for visualisation and 3D printing but contain no intelligence about holes, planes or cylinders. CAD systems like SolidWorks or Fusion 360 cannot directly convert these meshes into editable parametric models without additional reverse-engineering work.

LiDAR scanners generate point clouds—individual points with coordinates and often colour values. Point clouds are perfect for surveying, clash detection, volume calculations and as-built documentation. They are not intended to be edited like CAD models; instead, engineers build new geometry over the top using the cloud as reference.

Understanding this distinction avoids disappointment. Neither scanner delivers a “one-click CAD model.” Human engineering judgement is always required.

Surface and Environmental Limitations

EinScan technology relies on optical cameras and projected light, which introduces several practical limitations:

- Shiny or black surfaces are difficult to capture

- Transparent plastics confuse the cameras

- Deep holes and narrow slots are often missed

- Sunlight can overpower the projected pattern

- Tracking can be lost on large flat surfaces

LiDAR systems are more tolerant of environment. They can operate outdoors, in dusty workshops and over long distances. However, they also struggle with highly reflective materials such as polished stainless steel or glass, and they require careful setup to avoid shadows and occlusions.

Workflow Considerations

A typical EinScan workflow looks like this:

- Prepare the part—often with scanning spray

- Capture multiple passes

- Clean and align the mesh

- Export STL/OBJ

- Rebuild geometry in CAD using the mesh as reference

This process suits reverse engineering of brackets, castings, vehicle parts and consumer products.

A LiDAR workflow is different:

- Set up the scanner at multiple locations

- Register scans together in software such as FARO Scene or Leica Cyclone

- Classify and clean the point cloud

- Use the cloud for measurements, modelling or BIM integration

This approach is ideal for as-built surveys, plant upgrades, brownfield design and digital twins.

Cost and Ownership

EinScan systems range from a few thousand to around twenty thousand dollars. They are accessible to small businesses and even serious hobbyists. Software is generally included, and the learning curve is manageable.

Terrestrial LiDAR scanners are capital equipment. Purchase prices often exceed $60,000–$100,000 before software, training and maintenance. For many companies it makes more sense to engage a specialist scanning provider when required.

Choosing the Right Tool

The decision should be driven by the problem you are solving:

Choose EinScan when you need to:

- Create a bracket to fit an existing motor

- Reverse engineer a plastic enclosure

- Modify a vehicle component

- Capture complex organic shapes

- Produce meshes for 3D printing

Choose LiDAR when you need to:

- Document an industrial facility

- Design around existing plant and pipework

- Perform clash detection for upgrades

- Measure volumes and clearances

- Create a site-wide digital twin

Many organisations ultimately use both. A LiDAR scan provides the big picture, while an EinScan captures detailed components within that environment.

Integration with CAD

Engineers often ask which scanner works best with SolidWorks or Fusion 360. The honest answer is that neither integrates directly into parametric CAD without intermediate steps. EinScan meshes require reverse-engineering tools or manual modelling. LiDAR point clouds usually pass through Autodesk Recap, FARO Scene or similar before being referenced in CAD.

Scanning is a method of collecting truth, not generating finished design. The value lies in reducing site visits, avoiding clashes and giving designers confidence about existing conditions.

Final Thoughts

EinScan scanners and terrestrial LiDAR systems are not competitors; they are complementary tools on the reality-capture spectrum. One excels at objects on a bench, the other at assets spread across hectares. Selecting the wrong tool leads to frustration, while choosing correctly can transform the way projects are delivered.

For Australian fabricators and engineers, the key question is simple:

Are you capturing a part, or are you capturing a place?

Answer that, and the choice between EinScan and LiDAR becomes clear.