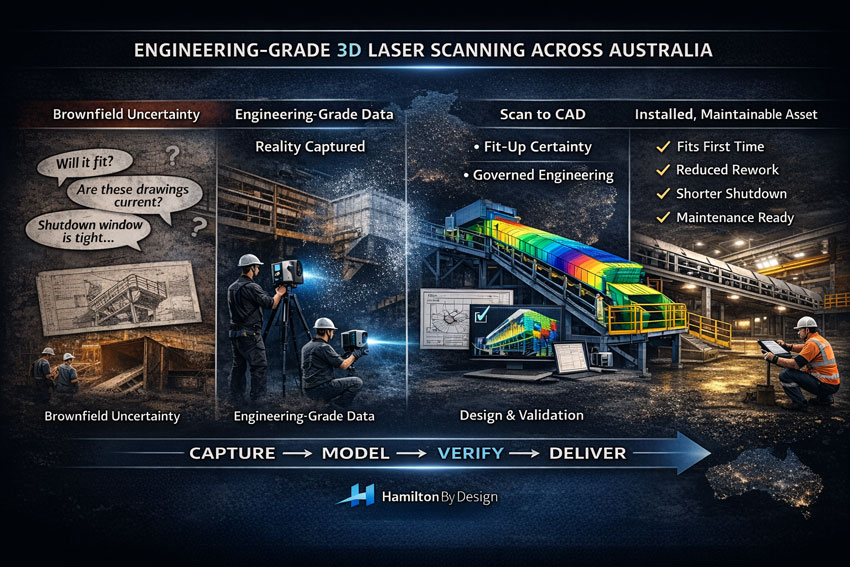

Papua New Guinea presents some of the most demanding industrial environments in the Asia-Pacific region. Remote terrain, ageing infrastructure, complex plant layouts and tight shutdown windows demand precision, efficiency and engineering certainty.

Hamilton By Design delivers engineering-grade 3D scanning services in Papua New Guinea, supporting mining, processing, infrastructure and industrial projects with accurate digital capture and practical engineering outcomes.

If you are planning a plant expansion, shutdown upgrade, brownfield modification or condition assessment in PNG, high-resolution laser scanning provides the clarity your project needs.

👉 Learn more about our dedicated PNG services here:

https://www.hamiltonbydesign.com.au/3d-scanning-papua-new-guinea/

Why 3D Laser Scanning Matters in PNG

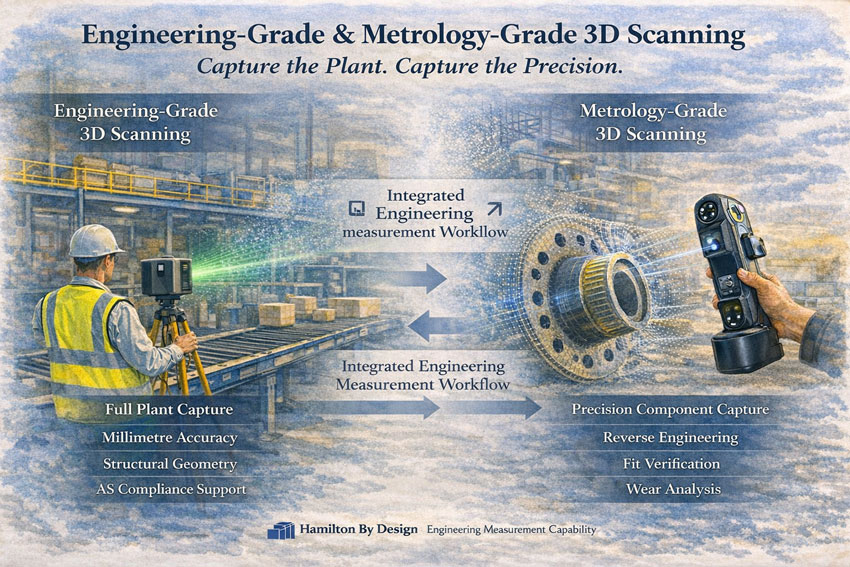

Traditional measurement methods are time-consuming and prone to error — especially in remote or operational sites. 3D laser scanning eliminates guesswork by capturing millions of precise data points in a matter of hours.

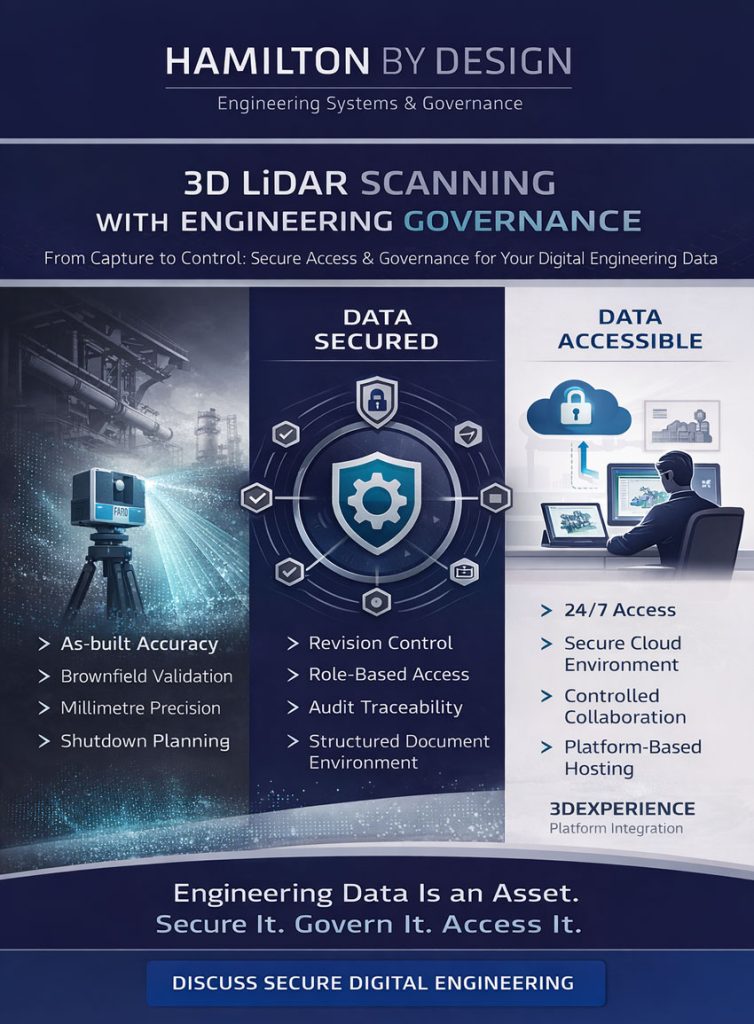

The result is a complete and reliable as-built digital record of your asset.

This enables:

- Accurate retrofit and tie-in design

- Reduced site revisits

- Improved shutdown planning

- Clash detection before fabrication

- Safer project execution

In remote PNG environments, reducing mobilisation and rework is not just convenient — it is critical to project success.

From Point Cloud to Engineering Outcome

At Hamilton By Design, we go beyond scanning.

We transform raw point cloud data into usable engineering outputs including:

- SolidWorks-ready 3D models

- Structural and mechanical layouts

- Fabrication drawings

- Design verification data

- Digital asset records

Our difference is simple: we are engineers first. Scanning is integrated directly into mechanical and structural design workflows, ensuring data captured onsite translates into practical, buildable solutions.

For a broader overview of our national capability, explore our full 3D laser scanning services here:

https://www.hamiltonbydesign.com.au/home/engineering-services/3d-laser-scanning/

Supporting Mining & Industrial Projects Across Papua New Guinea

Our PNG capability supports:

- Mining processing plants

- Conveyors and transfer stations

- Pump stations and pipework systems

- Structural steel and platforms

- Smelter and refinery infrastructure

- Brownfield plant upgrades

Whether your site is operational, remote or in early planning stages, we deliver data accuracy that reduces risk and accelerates decision-making.

Reduce Risk. Increase Certainty.

In complex industrial environments, uncertainty drives cost.

3D laser scanning provides:

- Accurate geometry

- Faster design cycles

- Reduced fabrication errors

- Improved stakeholder confidence

When combined with Hamilton By Design’s engineering capability, it becomes a powerful project delivery tool.

Delivering Engineering Certainty in Papua New Guinea

If your organisation is undertaking upgrades, expansions or asset assessments in Papua New Guinea, we are ready to support your project.

Explore our dedicated PNG scanning capability:

👉 https://www.hamiltonbydesign.com.au/3d-scanning-papua-new-guinea/

Or view our broader engineering-led 3D laser scanning services:

👉 https://www.hamiltonbydesign.com.au/home/engineering-services/3d-laser-scanning/