Robots are no longer the stuff of science fiction—they are embedded in our factories, warehouses, and even food-processing plants. They promise efficiency, speed, and the ability to take on dangerous jobs humans shouldn’t have to do. Yet, as recent headlines show, this promise comes with serious risks. From the lawsuit against Tesla over a robotic arm that allegedly injured a worker to the tragic death of a Wisconsin pizza factory employee crushed by a machine, the conversation about human–robot relations has never been more urgent.

This blog post explores the promise and peril of robotics in the workplace, drawing lessons from recent incidents and asking: how do we ensure humans and robots can coexist safely?

The Rise of Robotics in Everyday Work

Robotics is spreading quickly across industries. Automotive giants like Tesla rely on robotic arms for precision assembly, while food plants use automated systems to handle packaging and processing. According to the International Federation of Robotics, robot installations worldwide continue to grow year after year. For businesses, it’s a clear win: fewer errors, lower costs, and reduced human exposure to dangerous tasks.

But with robots entering smaller facilities—where safety infrastructure may be weaker—the risks grow. A miscalibrated robot, a missed safety step, or a poorly trained operator can turn a productivity tool into a deadly hazard.

When Robots Go Wrong: Lessons from Recent Cases

- Tesla’s Robotic Arm Lawsuit

A former technician at Tesla claims he was struck and knocked unconscious by a robotic arm while performing maintenance. The lawsuit highlights a crucial point: safety procedures like lockout/tagout aren’t optional—they are lifesaving. When machines are energized during servicing, even a momentary slip can have devastating consequences. - Wisconsin Pizza Factory Fatality

In a smaller manufacturing plant, a worker lost his life after being crushed by a robotic machine. Unlike Tesla, this wasn’t a high-tech car factory but a food facility—showing that robotics risks extend far beyond Silicon Valley. Smaller plants may lack robust safety training, yet they are increasingly embracing automation.

Both cases are tragic reminders that technology alone can’t guarantee safety. Human oversight, training, and organizational commitment to safety matter just as much.

The Human Side of Robotics

When people think about robots at work, they often picture job displacement. But for many workers, the immediate concern is safety. Studies show that trust plays a huge role: workers who believe robots are reliable tend to perform better. However, misplaced trust—assuming a machine will always stop when needed—can be just as dangerous as fear or mistrust.

Beyond physical risks, robots can also affect morale and mental health. Workers may feel devalued or expendable when machines take over critical tasks. The challenge isn’t just engineering safer robots—it’s creating workplaces where humans feel respected and protected.

Building a Safer Future Together

So how do we strike the right balance between robotics innovation and human well-being? A few key steps stand out:

- Design Safety Into the Machine: Emergency stops, advanced sensors, and fail-safes should be standard features—not optional add-ons.

- Enforce Safety Protocols: OSHA’s lockout/tagout rules exist for a reason. Employers must ensure that servicing robots without proper shutdowns is never allowed.

- Invest in Training: Robots are only as safe as the people who interact with them. Ongoing, practical training helps prevent accidents.

- Foster a Safety Culture: Workers should feel empowered to report unsafe practices without fear of retaliation.

- Update Regulations: As robots spread into more industries, regulators must adapt. International safety standards like ISO 10218 need to be more widely enforced, especially in smaller facilities.

Conclusion

Robotics is here to stay. It has the potential to make our workplaces more efficient, less physically demanding, and even safer. But incidents like those at Tesla and the Wisconsin pizza plant remind us that without proper safeguards, the cost of automation can be measured in human lives.

The future of human–robot relations doesn’t have to be one of fear or tragedy. With the right mix of engineering, regulation, and workplace culture, robots and humans can work side by side—not as rivals, but as partners. The question isn’t whether we should embrace robotics, but whether we’ll do so responsibly, putting people’s safety and dignity first.

Mechanical Engineering | Structural Engineering

Mechanical Drafting | Structural Drafting

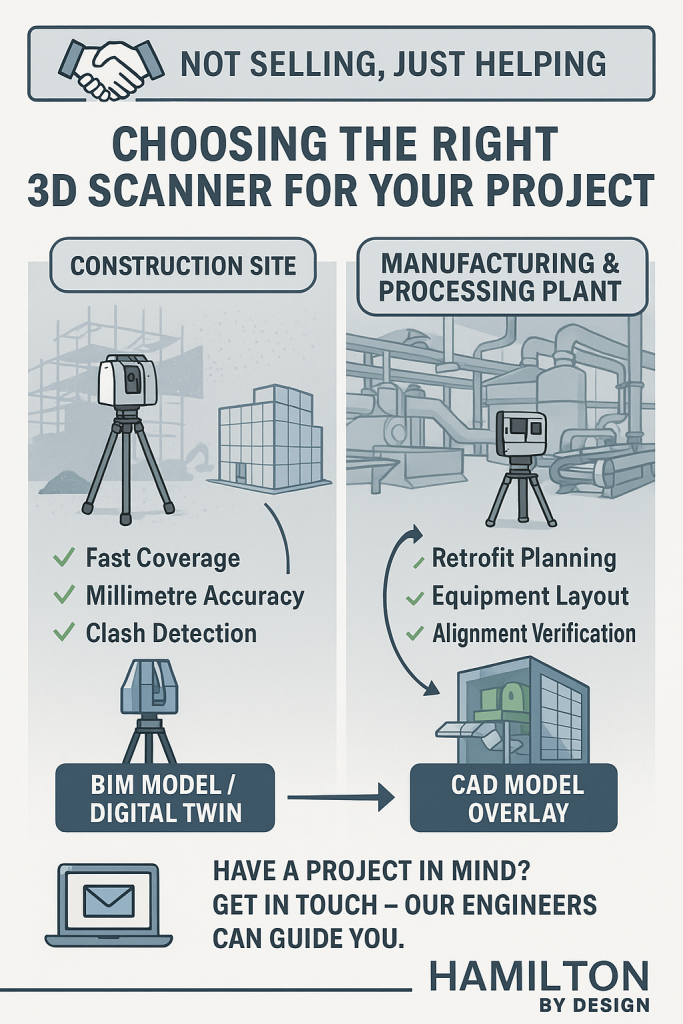

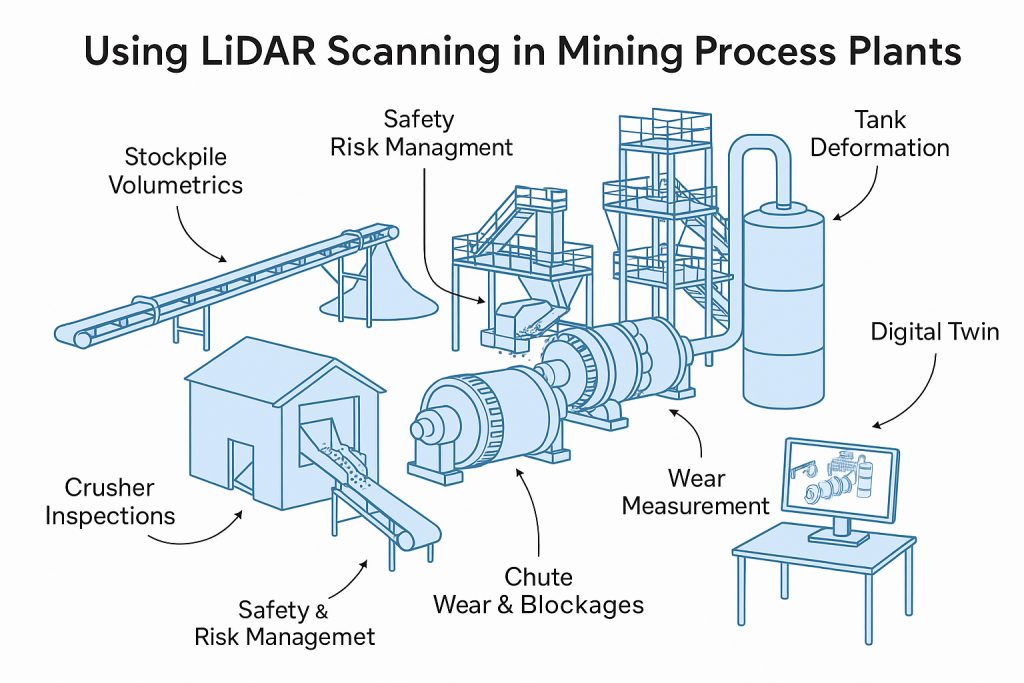

3D CAD Modelling | 3D Scanning

SolidWorks Contractors in Australia

Wisconsin pizza factory worker Robert Cherone crushed to death by robotic machine

Worker Sues Tesla After Alleged Robotic Arm Attack, Is Now Seeking Millions