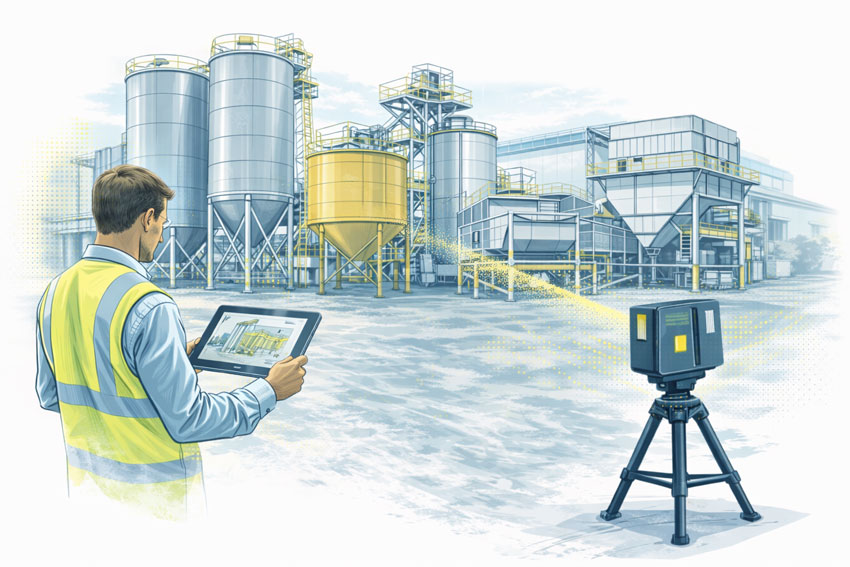

Engineering-Grade LiDAR for Accurate As-Built & Construction Delivery

Construction projects in Darwin operate in a demanding environment — tropical weather, remote logistics, accelerated schedules, and complex interfaces between structural, mechanical, and architectural elements. 3D construction scanning provides a reliable digital foundation to reduce risk, eliminate rework, and support confident decision-making throughout the project lifecycle.

Hamilton By Design delivers engineering-grade 3D construction scanning in Darwin, supporting contractors, engineers, builders, and asset owners with accurate spatial data, as-built models, and construction-ready documentation.

👉 Learn more about our Darwin scanning capability:

https://www.hamiltonbydesign.com.au/3d-scanning-in-darwin/

https://www.hamiltonbydesign.com.au/home/engineering-services/3d-scanning-darwin/darwin-lidar-laser-scanning-services/

What Is 3D Construction Scanning?

3D construction scanning uses high-accuracy LiDAR laser scanners to capture the real-world geometry of construction sites, partially completed works, and existing assets. The output is a dense, survey-grade point cloud that can be used to create:

- Accurate as-built drawings

- BIM and digital twin models

- Clash detection and coordination models

- Verification of construction tolerances

- Retrofit and upgrade designs

Unlike traditional tape or total-station methods, LiDAR captures millions of points per second, ensuring complex geometry is recorded correctly the first time.

Why 3D Construction Scanning Matters in Darwin

Construction in Darwin often involves:

- Live brownfield sites

- Remote or logistically constrained projects

- Tight shutdown or installation windows

- High consequences of dimensional errors

3D construction scanning enables:

✔ Reduced rework and RFIs

✔ Improved trade coordination

✔ Accurate verification before fabrication

✔ Faster design and approval cycles

✔ Safer site data capture with minimal disruption

This is particularly valuable for industrial buildings, ports, power generation facilities, defence infrastructure, and commercial developments across the Northern Territory.

Typical Construction Applications

As-Built Verification

Confirm what has actually been built — not what was assumed — before handover, certification, or the next construction stage.

Construction Progress Capture

Document progress at key milestones to support planning, claims, and coordination.

Retrofit & Upgrade Projects

Capture existing structures accurately before mechanical, electrical, or structural upgrades commence.

Clash Detection & Coordination

Overlay scanned data with design models to identify clashes early and avoid costly site changes.

Engineering-Led Scanning — Not Just Data Capture

At Hamilton By Design, 3D construction scanning is delivered by engineers, not just scanning technicians. This means:

- Scan strategies aligned to engineering outcomes

- Data captured at appropriate accuracy for construction tolerances

- Deliverables tailored for CAD, BIM, and fabrication workflows

- Clear accountability from scan to design to documentation

Our scanning integrates directly with mechanical design, structural analysis, and construction documentation services — providing a single source of truth for your project.

Deliverables to Suit Construction Teams

Depending on your requirements, we can provide:

- Registered point clouds

- CAD-ready models

- Revit / BIM outputs

- Section views and construction references

- Engineering drawings derived from scan data

All deliverables are tailored to suit builders, engineers, subcontractors, and asset owners.

Our clients:

3D Construction Scanning Darwin — Partner with Confidence

Whether you are delivering a new build, managing a complex refurbishment, or upgrading an existing facility, 3D construction scanning in Darwin provides the clarity and accuracy needed to build with confidence.

Hamilton By Design supports construction projects across Darwin and the Northern Territory with engineering-grade LiDAR scanning, practical deliverables, and real-world construction experience.

Let Connect us to discuss your project requirements or arrange a site scan.