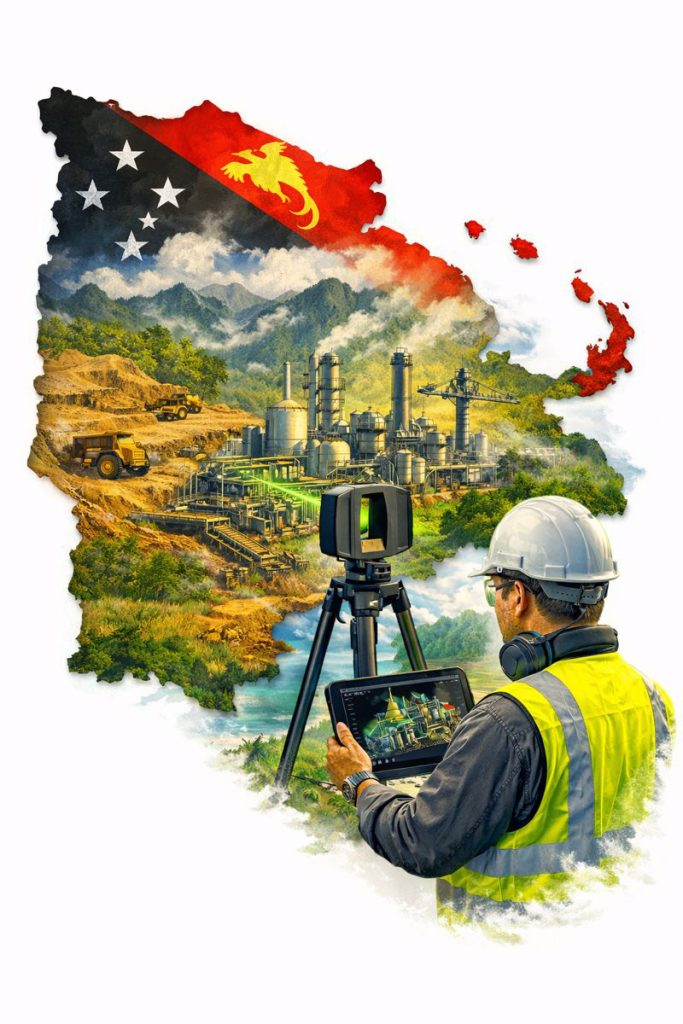

Reality capture that stands up to design, fabrication and installation in remote industrial environments

Papua New Guinea (PNG) is home to complex, high-value industrial assets — from mining and mineral processing plants through to ports, power generation and remote infrastructure. These projects are often delivered under tight shutdown windows, difficult logistics and challenging environmental conditions.

In these environments, engineering-quality 3D scanning is not a “nice to have” — it’s a practical tool that reduces risk by capturing accurate as-built conditions and converting them into deliverables engineers can trust.

Hamilton By Design provides engineering-led LiDAR scanning and scan-to-CAD modelling workflows designed for real project outcomes: upgrades that fit, installations that align, and drawings that reflect reality.

Why “Engineering Quality” Matters in PNG

Remote projects can’t afford rework.

When access is limited and mobilisation costs are high, even a small design error can cause major delays:

- fabricated components don’t fit

- tie-ins clash with existing pipework

- platforms and handrails foul equipment clearances

- shutdown windows blow out due to unexpected constraints

Engineering-quality reality capture reduces these risks by ensuring design starts from verified geometry — not assumptions or outdated drawings.

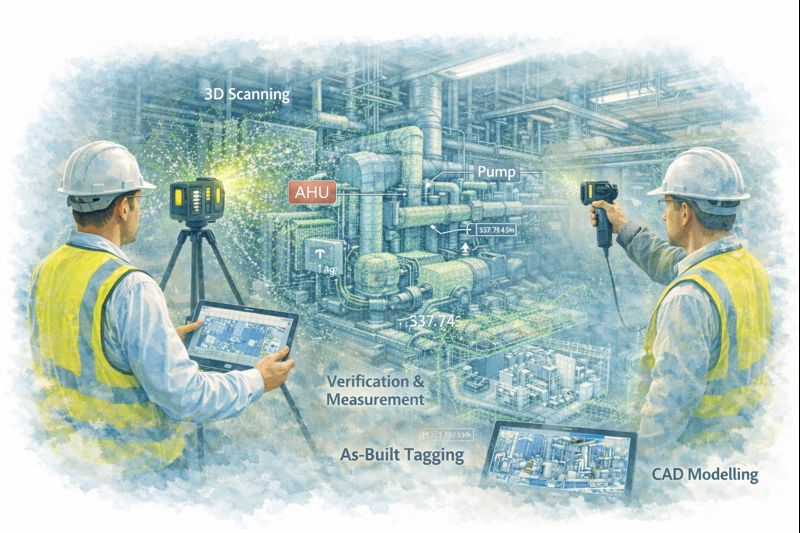

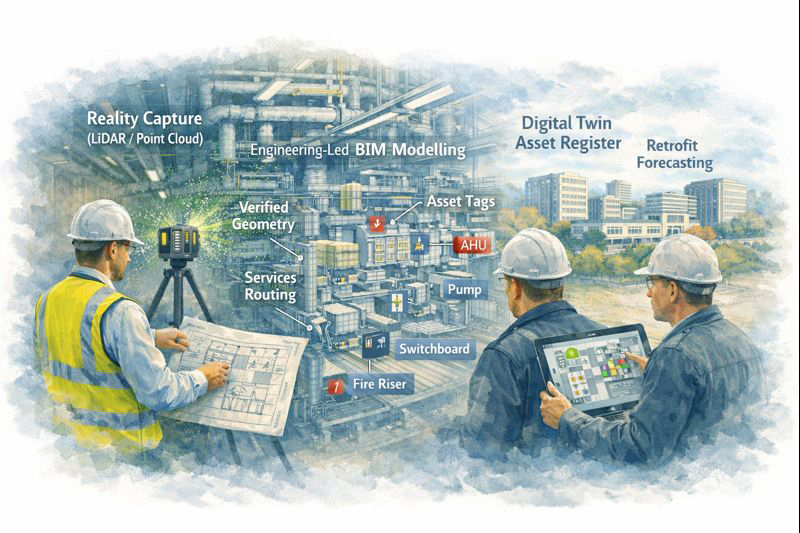

What Engineering-Quality 3D Scanning Includes

Not all scanning services deliver engineering-grade outcomes. “Engineering quality” means the capture and deliverables are suitable for mechanical and structural decisions, including fabrication and installation.

Key elements include:

- Survey control and consistent site referencing (where required)

- Defined accuracy targets aligned to project tolerances

- Registration QA and documented checks

- Clear deliverables (E57/RCP/RCS, CAD models, drawings)

- Model verification against point cloud prior to issue

The goal is simple: data you can design from.

Typical PNG Use Cases

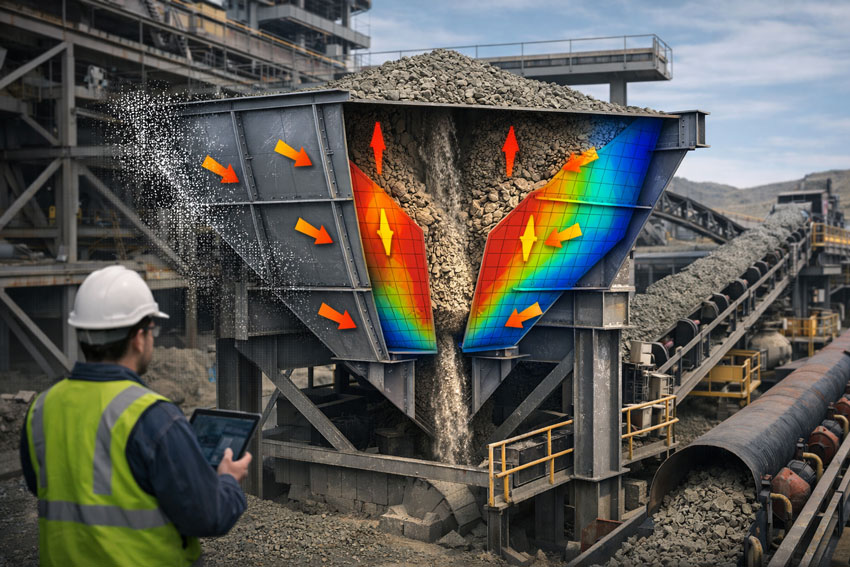

1) Plant Upgrades and Brownfield Modifications

For conveyors, chutes, pipework, pump skids, structural platforms and access upgrades, scanning provides accurate spatial context for clash-free design.

2) Shutdown Planning and Constructability Reviews

Point clouds help teams plan:

- access routes and lifting paths

- installation sequencing

- workpack scoping and constraints

This is especially valuable when shutdown windows are short and remote support is required.

3) Scan-to-CAD for Fabrication and Fit-Up

When components must be fabricated off-site and installed first time, engineering-grade LiDAR scanning provides the geometry needed for:

- interface modelling

- connection detailing

- fabrication drawings

4) As-Built Documentation and Asset Records

Many sites have incomplete legacy drawings. A scanned dataset can become the “single source of truth” for future upgrades and maintenance planning.

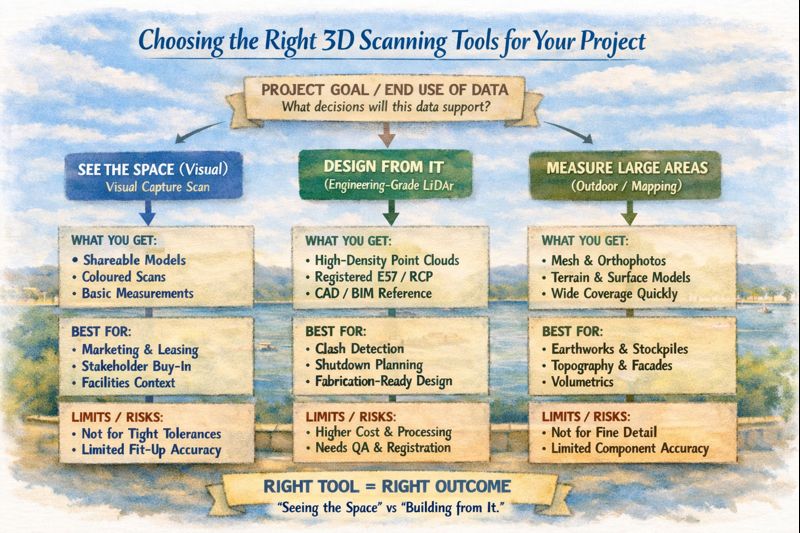

Choosing the Right Scanning Tool for PNG Conditions

PNG sites often include large structures, dense plant, tight access and harsh environmental conditions. In these cases, engineering-grade LiDAR is typically required because it provides:

- long-range capture across large facilities

- reliable geometry in low-light / indoor areas

- accuracy suitable for engineering design decisions

Other capture methods (visual scanning or photogrammetry) can be useful for context and surfaces, but if fabrication, tie-ins, and fit-up matter, LiDAR is usually the right choice.

Deliverables That Engineers Actually Use

Engineering-quality reality capture is only valuable if it becomes practical outputs.

Common deliverables include:

- Registered point clouds (E57 / RCP / RCS)

- 2D layouts, sections and elevations extracted from scans

- Scan-to-CAD models (structural, mechanical, piping)

- Interface models for replacement components

- Verification snapshots and check notes (QA evidence)

How We Manage Quality on Remote Projects

Remote work demands a higher standard of planning.

An engineering-quality workflow typically includes:

- Scope definition (what decisions will rely on the data?)

- Accuracy targets set to match the engineering requirement

- Capture plan (coverage, control, safe access, shutdown constraints)

- Registration + QA checks (repeatability, closure error, spot checks)

- Model extraction and verification against point cloud

- Issue deliverables in formats aligned to the project team

This approach reduces site revisits and ensures the data is fit for purpose.

Why Engineering-Led Reality Capture Matters

3D scanning becomes far more valuable when it’s integrated with mechanical and structural engineering — because the deliverables are designed to support:

- design decisions

- fabrication requirements

- installation sequencing

- long-term asset management

Engineering-led reality capture means scanning is not the end product — it is the foundation for a better engineering outcome.

Final Thoughts

For industrial projects in Papua New Guinea, engineering-quality 3D scanning helps teams deliver upgrades with confidence — particularly where logistics are difficult, shutdown time is limited, and “measure twice” is expensive.

If the project depends on fit-up, constructability and accurate as-built conditions, start with reality capture that is designed for engineering — not just visualisation.