3D LiDAR Scanning & Digital Verification Services

Accuracy. Confidence. Zero Surprises.

Hamilton By Design provides high-accuracy 3D LiDAR scanning and digital verification services for power stations, construction sites, commercial buildings, process plants, manufacturing facilities, CHPPs, and hard-rock processing plants.

Whether you’re validating prefabricated components before delivery, capturing an as-built model of a complex site, or ensuring a seamless retrofit, LiDAR scanning gives you the accuracy and confidence to deliver work right the first time.

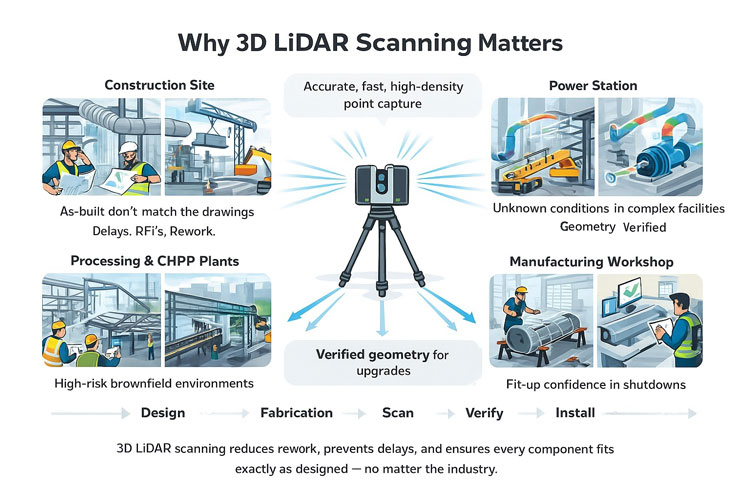

Why 3D LiDAR Scanning Matters

Across every industry, projects fail when the real conditions don’t match the design.

LiDAR scanning captures millions of measurement points in seconds, producing a precise digital representation of:

- existing structures

- new prefabricated components

- installation interfaces

- congested brownfield or construction environments

This data dramatically reduces rework, delays, and unexpected on-site conflicts.

A Complete Digital Quality Assurance Workflow

Hamilton By Design specialises in using LiDAR scanning as part of a Quality Assurance process before components leave the workshop.

We scan and digitally verify:

- Prefabricated chutes, spools, frames, platforms and modules

- Mechanical assemblies and welded fabrications

- Structural steel packages

- OEM components and machine parts

- Pipework, manifolds and fit-up geometry

- Custom prototypes and small-batch manufactured parts

Why QA Scanning Makes a Difference

3D scans allow you to:

- Detect dimensional errors before transport or installation

- Compare as-built components against design models

- Produce deviation reports for workshop fabrication teams

- Validate bolt patterns, flange faces, and interfaces

- Ensure accurate fit-up onsite — eliminating “red hot” cutting or rework

- Provide clients with digital QA evidence as part of project handover

This is becoming the new standard for high-quality fabrication and modular construction across Australia.

Where We Scan

We support a wide range of industries, including:

Power & Energy

- Coal-fired power stations

- Gas turbine halls & pump rooms

- Boiler houses and turbine floors

- Cooling water systems and pipe racks

Construction & Building

- Commercial building sites

- Structural frames and steel packages

- Car parks, basements, and services

- Facades and architectural installations

Processing & Heavy Industry

- CHPP plants and coal handling systems

- Hard rock mineral processing plants

- Conveyors, transfer stations, and screenhouses

- Crushers, mills, launders, hoppers and bins

Manufacturing & Fabrication

- Workshops and production lines

- Machinery, jigs, fixtures and assembly lines

- Prefabricated modules and large welded structures

Data Centres & Industrial Infrastructure

- Mechanical plant rooms

- HVAC systems, switchrooms and battery rooms

- Services coordination and verification

If it needs to be measured, validated, reverse-engineered, or digitally recorded — we can scan it.

Our 3D Scanning & Modelling Process

1. Scope & Planning

We align with your engineering, QA, or construction team to define:

- areas or components to be scanned

- required tolerances

- reference datums and control

- delivery formats (E57, RCP, SolidWorks, DWG, etc.)

2. LiDAR Data Capture

On-site or in your workshop, we perform high-resolution scanning using multiple positions to eliminate shadows and ensure 360° coverage.

3. Point Cloud Registration

Scans are combined, cleaned and aligned to your coordinate system or workshop datum.

4. Digital Verification

We can provide:

- as-built point clouds

- 3D SolidWorks models

- deviation maps (colour distance reports)

- interface verification

- bolt and flange alignment checks

- measurement reports for QA signoff

5. Deliverables

We supply practical, engineering-ready files that integrate directly into your design workflow:

- E57 / RCP point clouds

- SolidWorks assemblies and STEP models

- 2D drawings and reports

- Fit-up and clash analysis

- Fabrication QA evidence packages

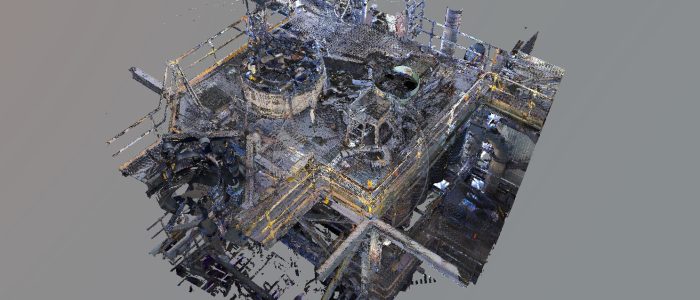

Point Clouds

Applications Across Industry

Quality Assurance Before Shipment

Ensure workshop-fabricated parts fit on-site before transport, reducing downtime and costly rework.

As-Built Capture & Digital Twins

Create accurate digital models to support future upgrades, maintenance planning or construction stages.

Retrofit & Brownfield Upgrades

Overlay new designs on real-world conditions to detect clashes early.

Construction Validation

Verify progress, alignment and installation accuracy on building sites and industrial projects.

Reverse Engineering

Capture hard-to-measure or legacy components to rebuild, redesign or certify replacements.

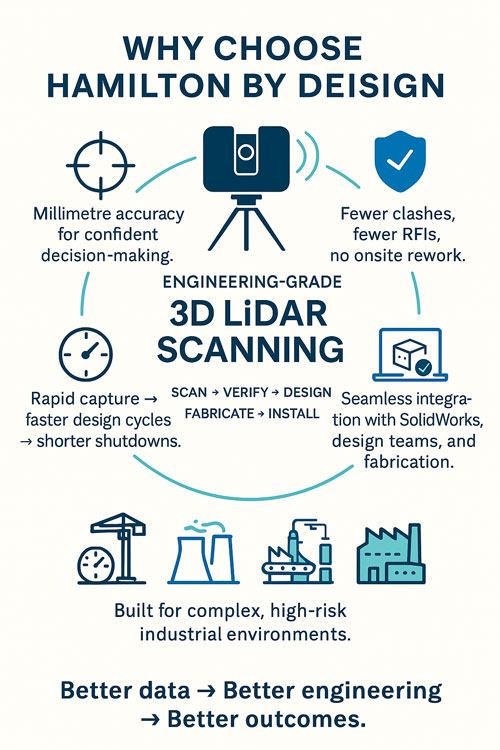

Why Choose Hamilton By Design?

- Engineer-led scanning — ensuring accuracy, context, and practical interpretation.

- End-to-end workflow — scanning, modelling, verification and design under one roof.

- Works across all industries — from power stations to precision manufacturing.

- High standards of QA — suitable for shutdown-critical, safety-critical and compliance-driven projects.

- Flexible deliverables — we provide point clouds, engineering models or full digital QA reports.

Our goal is simple: eliminate uncertainty before your project reaches site.

Start Your Scanning Project Today

Whether you need workshop QA, brownfield scanning, construction verification or a complete digital twin — we can help.