Melbourne hosts some of Australia’s largest engineering, fabrication, and industrial project teams. Hamilton By Design provides high-accuracy 3D laser scanning, point-cloud modelling, and fabrication-ready engineering that supports projects across the CBD, northern manufacturing precincts, and major industrial corridors.

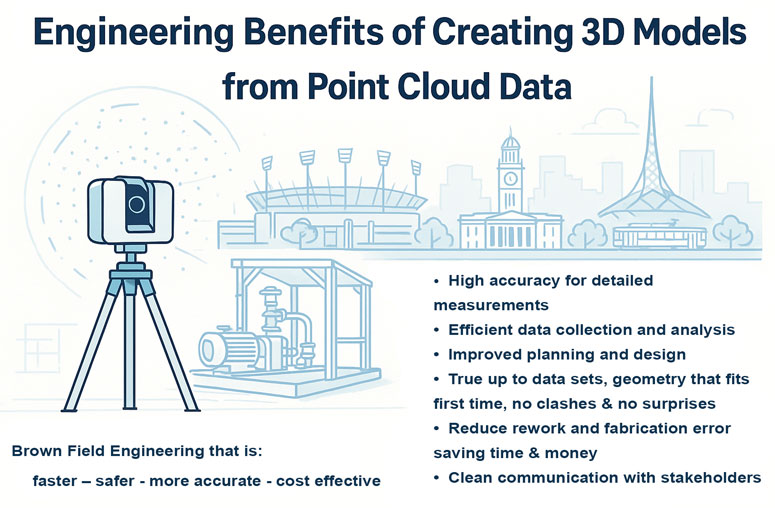

Whether you’re upgrading brownfield plant, validating as-built conditions, or preparing a new fabrication package, our scan-to-model workflow ensures your work fits first time, every time.

Why Melbourne Chooses 3D Laser Scanning for Engineering Projects

Fast, accurate data for complex industrial environments

- Millimetre-accurate as-built geometry

- No shutdown required for most scans

- Safely capture hard-to-access or hazardous areas

Better engineering decisions

- True as-built point clouds

- Clash-free design

- Better layout planning

- Stronger understanding of interfaces and constraints

Reduced rework and project delays

- Eliminate incorrect measurements

- Avoid onsite modifications

- Reduce fabrication errors

- Simplify installation and commissioning

Where We Deliver 3D Laser Scanning Across Melbourne

“We remove project risk by combining high-accuracy scanning, engineering judgement, and construction-ready documentation under one accountable team.” – Anthony Hamilton

Melbourne’s industrial and engineering sectors commonly requiring scanning include:

1. Manufacturing Precincts

- Campbellfield

- Thomastown

- Dandenong South

- Sunshine West

- Broadmeadows

Typical projects:

- Equipment skids

- Process piping

- Assembly jigs

- Heavy fabrication QA

2. Inner-City Infrastructure

- Yarra River bridges

- Tram depots

- Tunnels, stations, public assets

- Civil upgrades around Docklands and CBD

Projects include:

- Structural interfaces

- Brownfield works

- Fit-for-purpose access and maintenance upgrades

3. Food, Beverage & Pharmaceutical Plants

- West Melbourne

- Port Melbourne

- Clayton & Notting Hill biotech precinct

Typical scanning:

- Stainless piping

- Conveyor systems

- Plant expansions

- Services coordination

4. Power, Utilities & Water Treatment

Sites across:

- Werribee

- Eastern Treatment Plant

- Newport & Laverton industrial zones

Scanning supports:

- Pump stations

- Tanks

- Filtration systems

- Valve changes

- Platform and access upgrades

5. Fabrication Workshops Throughout Greater Melbourne

High-accuracy pre-delivery QA for:

- Structural frames

- Pump skids

- Modular process rooms

- Pipe spools

- Chutes and transfer systems

Ensure your fabrication matches the client’s as-built plant before it leaves the workshop.

Our Scan-to-Engineering Workflow

1. On-Site 3D Laser Scan

Using high-accuracy terrestrial scanners, we capture all mechanical, structural, and spatial geometry.

2. Point Cloud Processing

We register and clean the data to produce engineering-grade point clouds.

3. CAD Modelling

We convert the point cloud into:

- SolidWorks models

- STEP or Parasolid geometry

- Fabrication drawings

- Interface surfaces

4. Engineering Validation

We check:

- Flange alignment

- Centreline accuracy

- Structural fit

- Access and maintenance space

- Clash-free positioning

5. Digital Deliverables

Delivered in the format your engineering or fabrication team needs.

Why Melbourne Clients Choose Hamilton By Design

- Trusted by mining, energy, fabrication, and industrial clients across Australia

- Strong mechanical engineering background (not just scanning technicians)

- Deep experience with brownfield upgrades & shutdown constraints

- Ability to support remote sites from Melbourne-based engineering teams

- Everything designed to go together first time

Ready to Start Your Melbourne 3D Laser Scanning Project?

Email – info@hamiltonbydesign.com.au

Phone – 0477002249

Get in touch for:

- On-site scanning

- CAD modelling

- Fabrication-ready design

- Brownfield upgrades

- QA verification before shipping

Hamilton By Design – Engineering-grade accuracy for complex mechanical projects.

3D Laser Scanning

3D LiDAR Scanning – Digital Quality Assurance

3D Scanning for Construction in Sydney

Transforming Projects with 3D Scanning in Sydney

Our clients: