Safety and Precision in Mechanical Engineering Lifts

In the fast-paced world of Sydney construction and infrastructure, precision lifting is an everyday necessity. From hoisting prefabricated modules on high-rise towers to positioning steel frameworks and heavy plant components, each lift depends on one critical factor — the integrity of the lifting device.

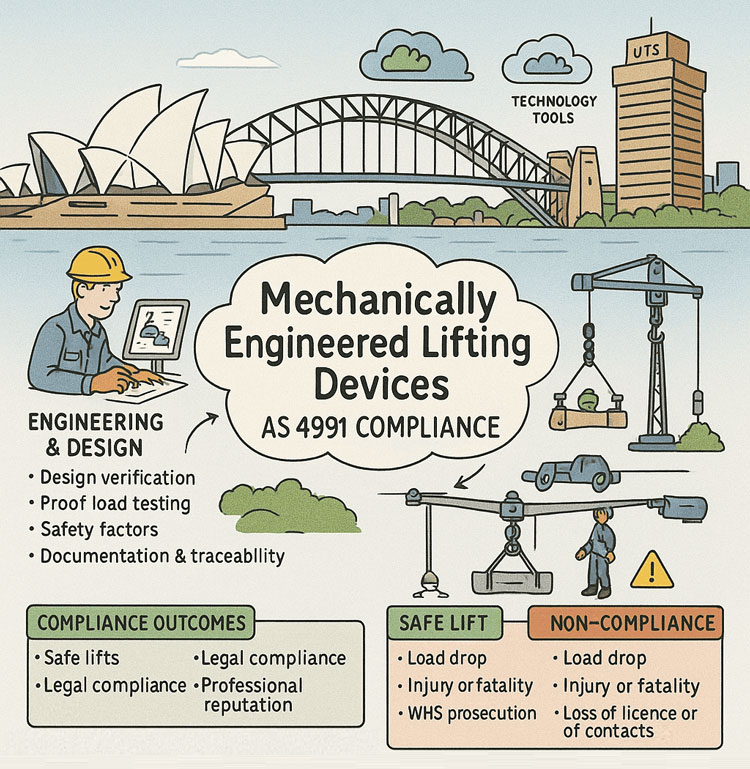

A mechanical engineering lift is more than just machinery; it’s the result of careful design, analysis, and compliance with national safety standards. The Australian Standard AS 4991: Lifting Devices provides the engineering framework to ensure that every lifting beam, clamp, and spreader frame is designed, tested, and certified for safe performance.

In the dynamic environment of Sydney’s construction and manufacturing sectors, adhering to AS 4991 is not only a compliance issue — it’s essential to safety, reliability, and professional reputation.

What AS 4991 Means for Mechanical Engineering in Sydney

AS 4991: Lifting Devices is the Australian benchmark for the design, manufacture, proof testing, and maintenance of all mechanically engineered lifting attachments used with cranes and hoists.

It covers:

- Design verification by qualified engineers

- Proof load testing (typically 1.5 times the Working Load Limit)

- Identification markings such as WLL, serial number, and manufacture date

- Regular inspection and maintenance schedules

- Documented certification and traceability

For Sydney-based mechanical engineering projects — from Parramatta’s commercial developments to the infrastructure of the Eastern Suburbs — these requirements ensure every lift is carried out with confidence and safety.

The Role of Mechanical Engineers in Safe Lifting

Mechanical engineers play a vital role in ensuring every lifting device performs predictably under real-world conditions. Each lifting beam, frame, or clamp must be:

- Designed for static and dynamic loading

- Resistant to fatigue, buckling, and corrosion

- Built from materials tested for strength and durability

- Verified through engineering analysis and proof testing

By applying AS 4991, mechanical engineers in Sydney create lifting devices that not only meet technical standards but also withstand the operational demands of construction, mining, and industrial settings across New South Wales.

Why Non-Compliance is Never Worth the Risk

Sydney’s worksites are under strict safety scrutiny, and incidents involving lifting equipment failures have resulted in serious injuries, fatalities, and prosecutions.

Examples from across Australia include:

- Unmarked or uncertified lifting beams that failed under load due to poor design.

- Vacuum lifters that detached unexpectedly after seals deteriorated from lack of inspection.

- Improvised lifting points on machinery leading to crush injuries and WHS enforcement actions.

These events share a common cause: failure to meet the design, inspection, and documentation requirements of AS 4991.

For any mechanical engineering lift in Sydney, non-compliance risks not just equipment damage but also:

- Work Health and Safety (WHS) prosecutions

- Civil negligence claims

- Loss of accreditation and contracts

- Damage to professional reputation

Compliance as a Legal and Professional Obligation

While AS 4991 is not legislation, it defines the expected standard of care under Australia’s WHS laws. Regulators such as SafeWork NSW use compliance with standards like AS 4991 as evidence of due diligence.

For mechanical engineers, fabricators, and construction managers, compliance means:

- Designs verified by competent engineers

- Devices tested and certified to meet load requirements

- Inspection records that prove ongoing safety

- Training to ensure operators understand correct usage

In Sydney’s competitive engineering market, adherence to AS 4991 isn’t just about avoiding penalties — it’s about demonstrating leadership in professional safety.

Building a Culture of Inspection and Traceability

A key part of AS 4991 is documentation. Each lifting device should have a design verification report, proof load certificate, and inspection record.

This traceability ensures that every lift on a Sydney site can be traced back to certified engineering.

Companies should maintain:

- A register of lifting devices with serial numbers and inspection dates

- Clear tagging systems for quick identification

- Routine re-certification for high-use environments

- Operator awareness training on compliance indicators

These processes turn safety standards into practical habits that protect workers and ensure smooth site operations.

Mechanical Engineering Lift Sydney: Innovation Meets Safety

Sydney is a hub of engineering innovation, with advanced tools like 3D scanning, LiDAR, and Finite Element Analysis (FEA) enhancing how lifting devices are designed and validated.

At Hamilton By Design, our mechanical engineers use these technologies to create custom lifting systems for complex sites across Sydney — from tight urban projects in Chatswood and Parramatta to industrial installations in the Inner West.

Yet, even with the latest modelling tools, every design is checked against AS 4991 to guarantee that each lift meets both engineering and safety expectations.

Conclusion: Lifting Sydney Safely

In mechanical engineering, safety begins long before the crane hook rises. It starts with standards — and in Australia, AS 4991 is the foundation.

For every mechanical engineering lift in Sydney, compliance ensures more than safety: it provides reliability, traceability, and peace of mind. By following the standard, engineers not only protect lives but also elevate the quality and professionalism of Sydney’s construction and manufacturing industries.

At Hamilton By Design, our commitment is simple: lift Sydney safely, lift with engineering excellence, and lift to the standard — AS 4991.

Our clients: