Accuracy That Builds Sydney Better

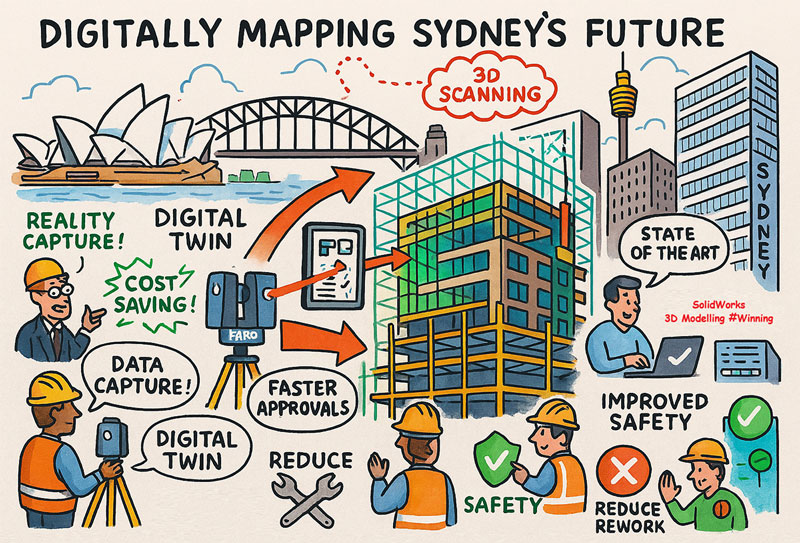

From the growing commercial hubs of Parramatta and Chatswood to the complex redevelopments across Sydney’s Eastern Suburbs, the construction industry is demanding more accuracy, faster turnaround, and fewer on-site surprises.

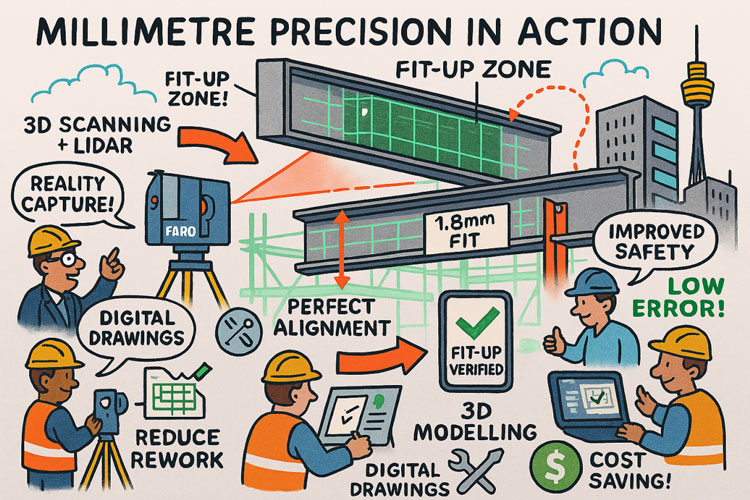

At Hamilton By Design, we use 3D scanning and LiDAR technology to help builders, engineers, and developers capture, model, and verify real site conditions with millimetre accuracy.

Our advanced 3D models ensure every structural, mechanical, or architectural component fits perfectly on site — helping Sydney’s construction professionals deliver projects right the first time.

High-Precision Site Capture with LiDAR Scanning

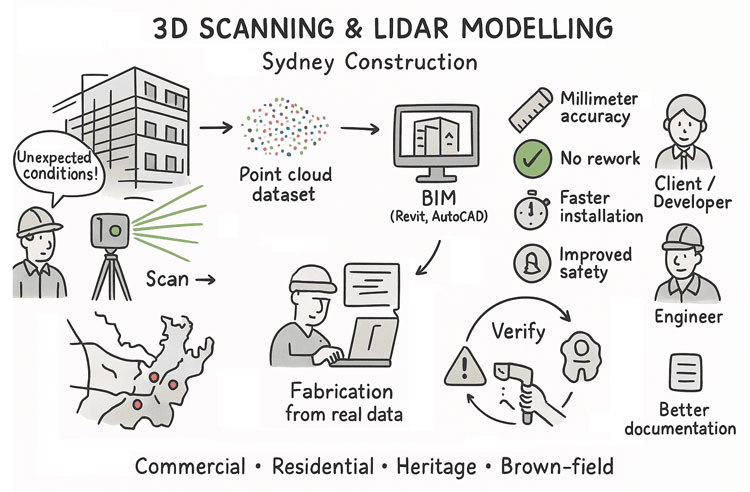

Using advanced LiDAR (Light Detection and Ranging) technology, our scanners record millions of laser points per second to create a complete 3D “point cloud” of your site or structure.

Whether we’re scanning a commercial building in Chatswood, a multi-level development in Parramatta, or a heritage renovation in Sydney’s Eastern Suburbs, LiDAR scanning allows us to document every detail — without disruption to your workflow.

The result is a digital twin of your project site that forms the foundation for precise design, fabrication, and installation.

From Point Cloud to Construction-Ready Model

Once scanning is complete, our engineers convert the LiDAR data into accurate 3D CAD and BIM models that integrate seamlessly into platforms such as Revit, AutoCAD, Navisworks, and SolidWorks.

This digital workflow allows your team to:

- Validate as-built conditions before design or fabrication

- Identify clashes and alignment issues early

- Plan site installations with confidence

- Reduce rework and delays during construction

By designing and fabricating to real-world data, Sydney contractors can save valuable time and eliminate unnecessary on-site adjustments.

Why Sydney Contractors Choose 3D Scanning and LiDAR

- Millimetre Accuracy: Perfect alignment between fabricated and existing structures.

- Reduced Rework: Detect and fix issues before they reach site.

- Improved Safety: Non-invasive scanning of hard-to-reach areas.

- Faster Installation: Minimise downtime and site delays.

- Better Documentation: Maintain accurate records for QA and future maintenance.

Across Chatswood, Parramatta, and Sydney’s Eastern Suburbs, our clients use LiDAR scanning to bring greater certainty to every phase of construction.

Supporting Projects Across Sydney

Hamilton By Design supports a wide range of construction and engineering projects across metropolitan Sydney, including:

- Commercial and retail developments in Chatswood and Parramatta

- Luxury residential projects and architectural fit-outs in Sydney’s Eastern Suburbs

- Industrial and infrastructure upgrades throughout Greater Sydney

- Brownfield and refurbishment projects requiring accurate as-built data

Whether it’s a new build or a complex retrofit, we make sure every part of your design fits the first time.

Partner with Hamilton By Design

If you’re managing or planning a construction project in Chatswood, Parramatta, or Sydney’s Eastern Suburbs, Hamilton By Design offers the experience and technology to capture, model, and verify your site with precision.

Our 3D scanning and LiDAR services help Sydney builders, designers, and fabricators deliver more accurate results — reducing risk, rework, and cost.

Mechanical Engineers in Sydney

Mechanical Engineering | Structural Engineering

Based in Sydney — servicing Chatswood, Parramatta, and the Eastern Suburbs

info@hamiltonbydesign.com.au

www.hamiltonbydesign.com.au

Capture. Model. Verify. Deliver.

Hamilton By Design — ensuring every project across Sydney fits perfectly, down to the last millimetre.

Our clients: