Engineering Projects

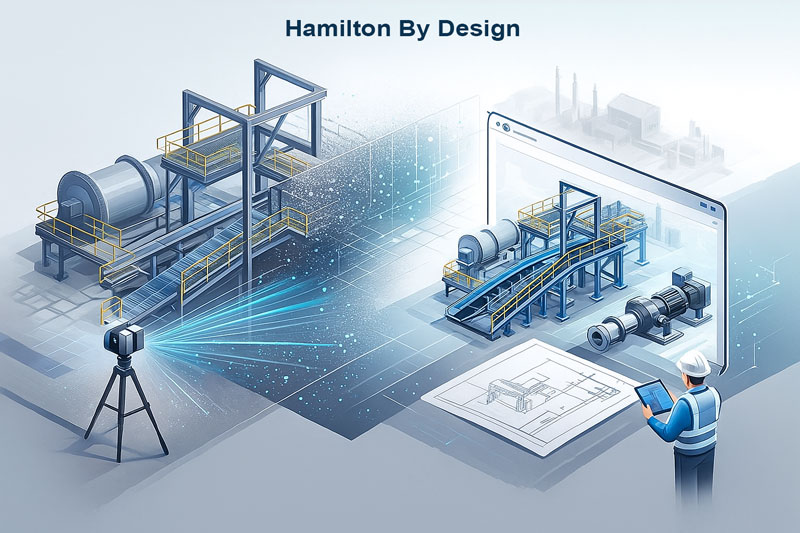

Engineering projects live or die on accurate measurements. Our 3D laser scanning service captures millions of data points in minutes, giving your team a precise digital replica of existing plant, structures or buildings. From there, we develop engineering-ready 3D models and drawings that help your designs fit first time, every time.

“We remove project risk by combining high-accuracy scanning, engineering judgement, and construction-ready documentation under one accountable team.” – Anthony Hamilton

Capture Reality. Engineer with Confidence.

High-accuracy 3D laser scanning and modelling for mechanical, structural and civil engineering projects.

- Millimetre-level as-built accuracy

- Engineering-ready 3D models and drawings

- Ideal for brownfield upgrades and retrofits

- Fewer site visits, clashes and rework

What Is 3D Laser Scanning for Engineering?

3D laser scanning uses LiDAR (Light Detection and Ranging) to capture millions of measurements of an asset, structure, plant or building. The result is a point cloud – a precise digital snapshot of the real world.

For engineering teams, this means:

- Reliable as-built data even in complex or congested areas

- Accurate geometry for piping, equipment, structures and access ways

- A solid foundation for 3D CAD models, BIM models and detailed drawings

Instead of relying on old drawings or manual tape-measure surveys, you work from a verified digital representation of what is actually on site.

Our Workflow – From Scan to Engineering-Ready Model

- Site Assessment & Planning

We review your scope, access constraints and safety requirements, then plan scan positions to capture the full area of interest with minimal disruption. - On-Site 3D Laser Scanning

Using a high-precision LiDAR scanner, we capture the environment from multiple positions – equipment, structures, conveyors, pipework, floor levels and more. - Point Cloud Registration & Cleaning

All scans are aligned into a single, accurate point cloud. We remove noise and check tolerances so the dataset is ready for engineering. - 3D Modelling & Detailing

Our team converts the point cloud into 3D models (e.g. structural steel, platforms, chutes, ducting, piping, equipment) using professional CAD tools such as SolidWorks or similar. - Engineering Deliverables

- 3D CAD models (STEP/SAT/SLDPRT/IFC etc.)

- General arrangement drawings

- Fabrication-ready shop drawings and spool drawings

- Clash checks and design/constructability reviews

- Ongoing Support

We’re available to update models, assist with design iterations and support your project through fabrication, installation and commissioning.

Applications Across the Engineering Lifecycle

- Brownfield Upgrades & Retrofits

Scan existing plant to design new equipment or structures that fit seamlessly into congested areas. - Fabrication & Installation Projects

Use 3D models derived from scans to create accurate fabrication drawings, reducing fit-ups, hot-work and rework during shutdowns. - Structural Engineering & Access

Capture frames, platforms, handrails, ladders and walk-ways to verify clearances, load paths and safe access. - Piping & Mechanical Systems

Model complex pipe runs, valves, flanges, pumps and tanks from the point cloud to support reroutes, revamps and tie-ins. - Plant Layout & Space Planning

Quantify available space and clearances for new equipment, ducting, conveyors or services. - Digital Twin & Asset Management

Use scan-derived models as the foundation for digital twins, asset registers and long-term maintenance planning.

Why Engineering Teams Use 3D Laser Scanning

- Reduced Site Time & Risk

Fewer manual measurements in difficult or hazardous areas. Once scanned, your team can “walk the site” virtually. - Better Design Decisions

With accurate as-built data, you can test design options, check clashes and validate clearances before committing to fabrication. - First-Time Fit

Fabrication drawings derived from accurate scans dramatically reduce rework, on-site modifications and shutdown delays. - Improved Communication

Point clouds and 3D models help engineers, project managers, fabricators and site teams all see the same information. - Traceability & Documentation

Save your scan data and models as a documented record of existing conditions at a point in time.

Engineering Projects

- Mining and mineral processing plants (CHPP, hard-rock, materials handling)

- Power generation and energy infrastructure

- Manufacturing and processing facilities

- Bulk materials handling (conveyors, chutes, reclaimers, stackers)

- Industrial buildings and warehouses

- Water and wastewater treatment plants

- Commercial and institutional buildings for engineering upgrades

What You Receive

Deliverables You Can Plug Straight Into Your Workflow

We tailor outputs to suit your engineering tools and standards, including:

- Registered point clouds (E57, RCP/RCS, LAS etc.)

- 3D CAD models in your preferred format

- 2D drawings (GA, fabrication, detailing)

- Reports and mark-ups highlighting clashes, interferences or key dimensions

- Optional visualisations and walkthroughs for stakeholders

FAQs

Frequently Asked Questions

Q: How accurate is the 3D scan?

A: Typical accuracy is within a few millimetres over the scan area, depending on the environment and range. For most mechanical and structural engineering applications, this is more than sufficient for design and fabrication.

Q: Can you work from our existing drawings?

A: Yes. We can align the point cloud to your plant coordinates or existing models, helping you verify old drawings and update them where required.

Q: Do I need specialist software to use the point cloud?

A: Not necessarily. We can supply viewer-friendly formats for simple measurements, as well as standard CAD formats for your engineering team.

Q: How much site access do you need?

A: Scanning is fast and non-contact. We usually work around your normal operations, coordinating with your site team to maintain safety and minimise disruption.

Ready to Use 3D Laser Scanning on Your Next Engineering Project?

Accurate as-built data is the fastest way to de-risk your next upgrade or installation. If you’re planning a brownfield project, fabrication package or plant modification, 3D laser scanning can save you time, money and stress.

3D LiDAR Scanning – Digital Quality Assurance

3D Point Clouds Are a Game-Changer for Your Projects

Your Experts in 3D Laser Scanning & Mechanical Design