In modern mining, where uptime is money and safety is non-negotiable, understanding the geometry of your process plant is critical. Every conveyor, chute, pipe rack, and piece of equipment must fit together seamlessly and operate reliably — but plants are messy, dusty, and constantly changing. Manual measurement with a tape or total station is slow, risky, and often incomplete.

This is where LiDAR scanning (Light Detection and Ranging) has become a game-changer. By capturing millions of precise 3D points per second, LiDAR gives engineers, maintenance planners, and operators an exact digital replica of the plant — without climbing scaffolds or shutting down equipment. In this post, we’ll explore how mining companies are using LiDAR scanning to solve real problems in processing plants, improve safety, and unlock operational efficiency.

What Is LiDAR Scanning?

LiDAR is a remote sensing technology that measures distance by firing pulses of laser light and recording the time it takes for them to return. Modern terrestrial and mobile LiDAR scanners can:

- Capture hundreds of thousands to millions of points per second

- Reach tens to hundreds of meters, depending on the instrument

- Achieve millimeter-to-centimeter accuracy

- Work in GPS-denied environments, such as inside mills, tunnels, or enclosed plants (using SLAM — Simultaneous Localization and Mapping)

The output is a point cloud — a dense 3D dataset representing surfaces, equipment, and structures with stunning accuracy. This point cloud can be used as-is for measurements or converted into CAD models and digital twins.

Why Process Plants Are Perfect for LiDAR

Unlike greenfield mine sites, processing plants are some of the most geometry-rich and access-constrained areas on site. They contain:

- Complex networks of pipes, conveyors, tanks, and structural steel

- Moving equipment such as crushers, mills, and feeders

- Dusty, noisy, and hazardous environments with limited safe access

All these factors make traditional surveying difficult — and sometimes dangerous. LiDAR enables “no-touch” measurement from safe vantage points, even during operation. Multiple scans can be stitched together to create a complete model without shutting down the plant.

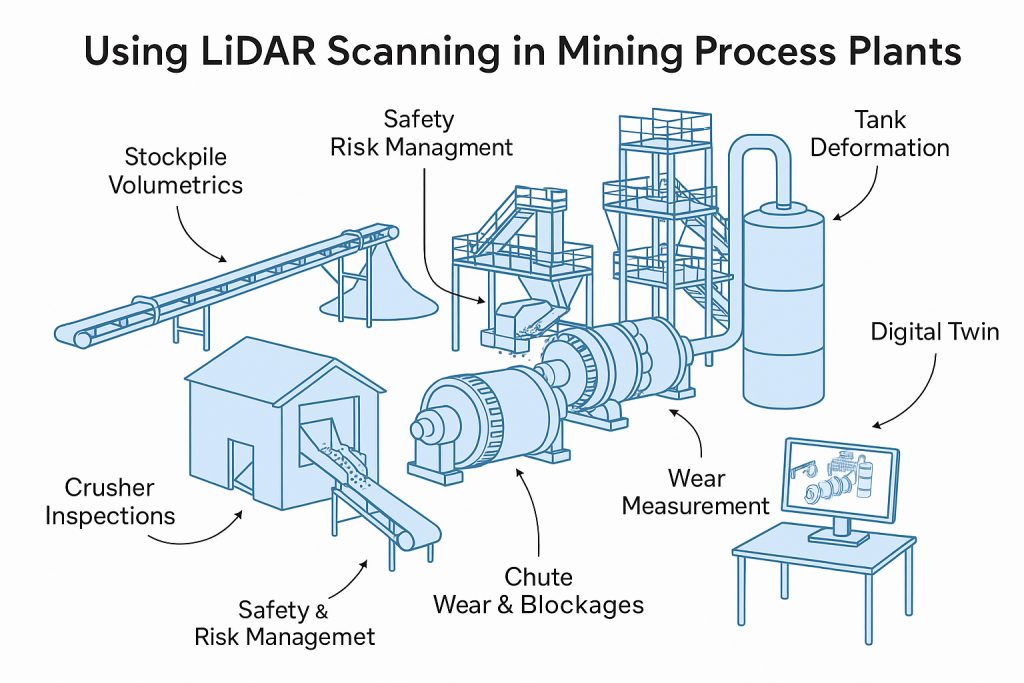

Applications of LiDAR in Process Plants

1. Wear Measurement and Maintenance Planning

LiDAR has revolutionized how mines measure and predict wear on critical process equipment:

- SAG and Ball Mill Liners – Portable laser scanners can capture the exact wear profile of liners. Comparing scans over time reveals wear rates, helping maintenance teams schedule relines with confidence and avoid premature failures.

- Crusher Chambers – Scanning inside primary and secondary crushers is now faster and safer than manual inspections. The resulting 3D model allows engineers to assess liner life and optimize chamber profiles.

- Chutes and Hoppers – Internal scans show where material buildup occurs, enabling targeted cleaning and redesign to prevent blockages.

Result: Reduced downtime, safer inspections, and better forecasting of maintenance budgets.

2. Retrofit and Expansion Projects

When modifying a plant — installing a new pump, rerouting a pipe, or adding an entire circuit — having an accurate “as-built” model is crucial.

- As-Built Capture – LiDAR provides an exact snapshot of the existing plant layout, eliminating guesswork.

- Clash Detection – Designers can overlay new equipment models onto the point cloud to detect interferences before anything is fabricated.

- Shutdown Optimization – With accurate geometry, crews know exactly what to cut, weld, and install — reducing surprise field modifications and shortening shutdown durations.

3. Inventory and Material Flow Monitoring

LiDAR is not just for geometry — it’s also a powerful tool for tracking material:

- Stockpile Volumetrics – Mounted scanners on stackers or at fixed points can monitor ore, concentrate, and product stockpiles in real time.

- Conveyor Load Measurement – Stationary LiDAR above belts calculates volumetric flow, giving a direct measure of throughput without contact.

- Blending Control – Accurate inventory data improves blending plans, ensuring consistent plant feed quality.

4. Safety and Risk Management

Perhaps the most valuable application of LiDAR is keeping people out of harm’s way:

- Hazardous Floor Areas – When flooring or gratings fail, robots or drones with LiDAR payloads can enter the area and collect data remotely.

- Fall-of-Ground Risk – High walls, bin drawpoints, and ore passes can be scanned for unstable rock or buildup.

- Escape Route Validation – Scans verify clearances for egress ladders, walkways, and platforms.

Every scan effectively becomes a permanent digital record — a baseline for monitoring ongoing structural integrity.

5. Digital Twins and Advanced Analytics

A plant-wide LiDAR scan is the foundation of a digital twin — a living, data-rich 3D model connected to operational data:

- Combine scans with SCADA, IoT, and maintenance systems

- Visualize live process variables in context (flow rates, temperatures, vibrations)

- Run “what-if” simulations for debottlenecking or energy optimization

As AI and simulation tools mature, the combination of geometric fidelity and operational data opens new possibilities for predictive maintenance and autonomous plant operations.

Emerging Opportunities

Looking forward, there are several promising areas for LiDAR in mining process plants:

- Autonomous Scan Missions – Using quadruped robots (like Spot) or SLAM-enabled drones to perform routine scanning in high-risk zones.

- Real-Time Change Detection – Continuous scanning of critical assets with alerts when deformation exceeds thresholds.

- AI-Driven Point Cloud Analysis – Automatic object recognition (valves, flanges, motors) to speed up model creation and condition reporting.

- Integrated Planning Dashboards – Combining LiDAR scans, work orders, and shutdown schedules in a single interactive 3D environment.

Best Practices for Implementing LiDAR

To maximize the value of LiDAR scanning, consider:

- Define the Objective – Are you measuring wear, planning a retrofit, or building a digital twin? This affects scanner choice and resolution.

- Plan Scan Positions – Minimize occlusions and shadow zones by preplanning vantage points.

- Use Proper Registration – Tie scans to a control network for consistent alignment between surveys.

- Mind the Environment – Dust, fog, and vibration can degrade data; choose scanners with appropriate filters or protective housings.

- Invest in Processing Tools – The raw point cloud is only the start — software for meshing, modeling, and analysis is where value is extracted.

- Train Your Team – Build internal capability for scanning, processing, and interpreting the results to avoid vendor bottlenecks.

LiDAR scanning is no longer a niche technology — it is rapidly becoming a standard tool for mining process plants that want to operate safely, efficiently, and with fewer surprises. From mill liners to stockpiles, from shutdown planning to digital twins, LiDAR provides a clear, measurable view of assets that was impossible a decade ago.

For operations teams under pressure to deliver more with less, the case is compelling: better data leads to better decisions. And in a high-stakes environment like mineral processing, better decisions translate directly to improved uptime, reduced costs, and safer workplaces.

The next time you’re planning a shutdown, a retrofit, or even just trying to understand why a chute is plugging, consider pointing a LiDAR scanner at the problem. You may be surprised at how much more you can see — and how much time and money you can save.

Mechanical Engineering | Structural Engineering

Mechanical Drafting | Structural Drafting

3D CAD Modelling | 3D Scanning