The Hunter Valley is home to some of Australia’s most significant power generation assets. These power stations — many of which have operated for decades — supply energy to mining operations, manufacturing facilities, regional communities and industries throughout New South Wales. As these plants age and undergo continual maintenance, upgrades and redevelopment, the importance of accurate, reliable and safe measurement methods becomes increasingly critical.

Traditionally, engineers and maintenance teams have relied on manual measurements, outdated drawings or partial documentation to plan upgrades or execute shutdown work. But in complex, congested and ageing plant environments, this introduces risks, delays and expensive rework.

This is why 3D LiDAR scanning in Hunter Valley power stations has emerged as one of the most valuable tools for modern asset management, engineering and maintenance planning. LiDAR provides a millimetre-accurate digital snapshot of real-world conditions, enabling smarter, safer and more predictable project outcomes.

This article explores the benefits, applications, and pros and cons of 3D LiDAR scanning and explains why Hunter Valley power stations stand to gain significantly from adopting this technology.

Why Power Stations Need Accurate As-Built Data

Power stations are among the most complex industrial facilities in Australia. Over decades of operation, they experience:

- Structural deformation

- Settlement and movement

- Corrosion and wear

- Numerous undocumented modifications

- Equipment realignments

- Tight access restrictions

- Ageing steelwork and infrastructure

In these environments, original construction drawings rarely match reality. As a result, engineers planning upgrades, shutdowns or replacements often face:

- Inaccurate interface points

- Misaligned structures

- Unpredictable installation conditions

- High rework costs

- Safety delays

- Poor shutdown timing

3D LiDAR scanning offers a precise, digital representation of the site, giving engineers the confidence they need to design upgrades accurately and eliminate guesswork.

The Benefits of 3D LiDAR Scanning for Hunter Valley Power Stations

1. Unmatched Measurement Accuracy for Complex Assets

A power station contains thousands of interconnected components:

- Boilers

- Turbines

- Structural platforms

- Pipe networks

- Pressure vessels

- Ducting systems

- Conveyor bridges

- Cooling towers

- Electrical cabinets

- Steel supports

Capturing these geometries manually is nearly impossible.

3D LiDAR scanning provides millimetre-level accuracy across enormous plant areas, allowing engineers to:

- Create precise as-built models

- Validate structural alignment

- Check pipe routes and clearances

- Identify interferences

- Understand deformation over time

- Design new works based on real geometry

This level of data is invaluable for maintaining safe and compliant power-generation operations.

2. Major Safety Improvements

Power stations present significant safety risks:

- High-voltage environments

- Confined spaces

- Elevated platforms

- Hot surfaces

- Restricted access

- Operational machinery

Manual measurement often requires workers to climb structures, enter hazardous zones or physically reach difficult areas.

3D LiDAR scanning dramatically reduces risk by:

- Capturing data from safe distances

- Eliminating the need for repeated access

- Reducing time in hazardous zones

- Minimising interaction with live equipment

For Hunter Valley power stations with strict safety requirements, this is a major benefit.

3. Reduced Shutdown Duration and Cost

Shutdowns are among the most expensive events for power-generation facilities. Every hour counts.

With 3D LiDAR scanning:

- Engineers define accurate scopes before shutdown

- Fabricators receive precise data and cut steel correctly

- Digital fit checks identify issues early

- Installation is faster and smoother

- Delays due to bad measurements are eliminated

This leads to shorter outages, safer work and fewer unexpected problems.

4. Supports Engineering, Design and Structural Integrity Works

Power stations frequently require:

- Boiler upgrades

- Turbine area modifications

- Ducting and flue replacements

- Pipework rerouting

- Cooling-system upgrades

- Structural strengthening

- Platform and walkway replacements

- Electrical equipment relocations

All of these tasks depend on accurate geometry.

3D LiDAR scanning supports engineering teams by providing:

- Reference geometry for load calculations

- Verified connection points

- True alignment data

- Accurate slope and deflection measurements

- High-resolution drawings and 3D models

This ensures engineering decisions are made using verified, real-world information.

5. Perfect for Brownfield and Congested Environments

Power stations are some of the most complex brownfield assets in the industrial landscape. They contain layers of modifications, years of retrofits and areas where access is extremely limited.

3D LiDAR scanning excels at capturing:

- Tight clearances

- Overlapping structures

- Equipment clusters

- Interconnected pipes

- Hard-to-reach surfaces

This makes it ideal for planning:

- New platforms

- Replacement ducting

- Pipe realignments

- Structural upgrades

- Asset lifecycle extensions

The result: fewer surprises during installation.

6. Better Collaboration Between Teams

Power stations typically involve:

- Maintenance teams

- OEMs

- Engineering consultants

- Fabricators

- Shutdown managers

- Safety personnel

- Project delivery teams

3D LiDAR scanning enables everyone to work from the same digital truth.

Point clouds and 3D models allow:

- Remote site understanding

- Clear communication

- Digital reviews instead of repeated site visits

- Improved planning alignment

For Hunter Valley projects involving multiple contractors, this significantly boosts performance.

Pros and Cons of 3D LiDAR Scanning

Like any technology, LiDAR has strengths and limitations. Understanding both helps power station operators make informed decisions.

⭐ Pros

✔ Extremely high accuracy

Millimetre precision for large and complex areas.

✔ Fast data capture

Reduces time spent in hazardous areas.

✔ Clear visibility of congested spaces

Captures geometry that traditional methods miss.

✔ Enhances engineering confidence

Designers base work on verified conditions.

✔ Reduces installation rework

Fabrication matches the real site exactly.

✔ Supports digital engineering workflows

Perfect input for CAD, BIM, simulation and modelling.

✔ Safer measurement practices

Less climbing, reaching and confined-space entry.

⭐ Cons

❌ Requires skilled interpretation

Point cloud data must be processed by trained technicians or engineers.

❌ Large file sizes

High-resolution scans require strong computing resources.

❌ Reflective or transparent surfaces can create challenges

Requires technique or matte marking in some areas.

❌ Upfront cost may seem higher

But it eliminates far greater downstream costs in rework and shutdown delays.

Despite these considerations, LiDAR scanning remains the most cost-effective measurement tool for power station environments.

Why Hunter Valley Power Stations Benefit More Than Most

The Hunter Valley industrial landscape presents unique challenges:

- Ageing energy infrastructure

- Multiple retrofits and undocumented modifications

- Extremely tight maintenance windows

- Harsh environmental conditions

- Congested structures with difficult access

- High safety standards

- Heavy reliance on local fabrication accuracy

3D LiDAR scanning Hunter Valley power stations provides the one thing these facilities need most: confidence.

Confidence in measurements.

Confidence in fabrication.

Confidence during shutdowns.

Confidence in engineering decisions.

Confidence in safety performance.

Few regions stand to gain more from LiDAR than the Hunter.

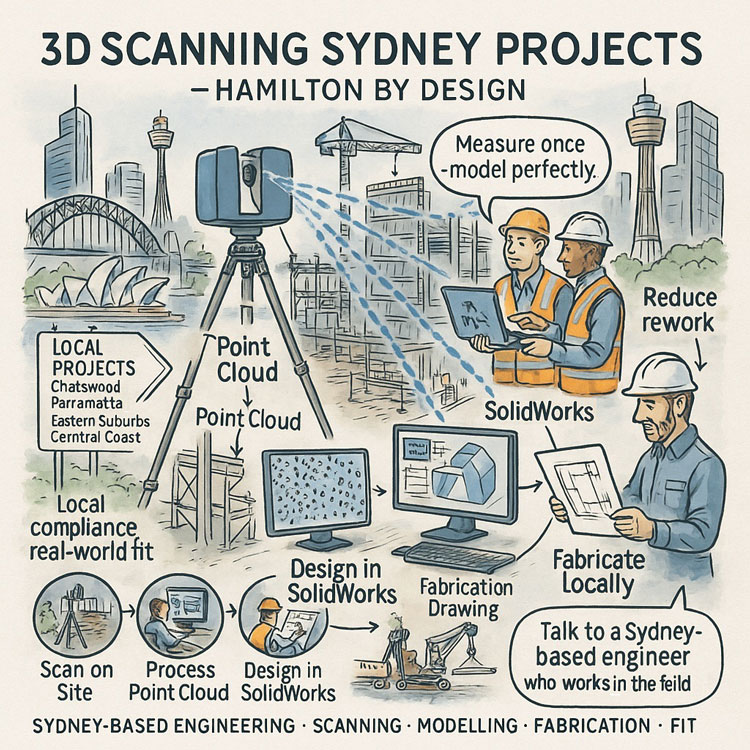

Hamilton By Design: Supporting Hunter Valley Power Stations with Advanced LiDAR Solutions

Hamilton By Design brings together:

- Engineering expertise

- On-site scanning capability

- CAD modelling and drafting

- Fabrication-ready documentation

- Digital fit-checking and clash detection

- Mechanical and structural design experience

We understand the complex realities of power-station environments, and we deliver precise, reliable and engineering-ready digital data for:

- Boiler upgrades

- Turbine hall modifications

- Structural replacements

- Pipe rerouting

- Platform and access upgrades

- Ducting and flue modifications

- Cooling tower projects

- Balance-of-plant improvements

Every model, point cloud and drawing is produced with installation success and fabrication accuracy in mind.

Conclusion: 3D LiDAR Scanning is the New Standard for Hunter Valley Power Stations

As the Hunter Valley transitions into a future of renewable generation, asset extension and industrial redevelopment, 3D LiDAR scanning stands out as a technology that delivers real, immediate value.

It improves safety.

It increases accuracy.

It reduces rework.

It enables better engineering.

It shortens shutdowns.

It lowers project risk.

Power stations across the Hunter Valley rely on critical, ageing and highly complex infrastructure — infrastructure that demands accurate, reliable digital measurement.

Hamilton By Design is proud to support the region with advanced laser scanning technologies that empower engineers, fabricators, supervisors and project managers to work smarter, safer and more efficiently.