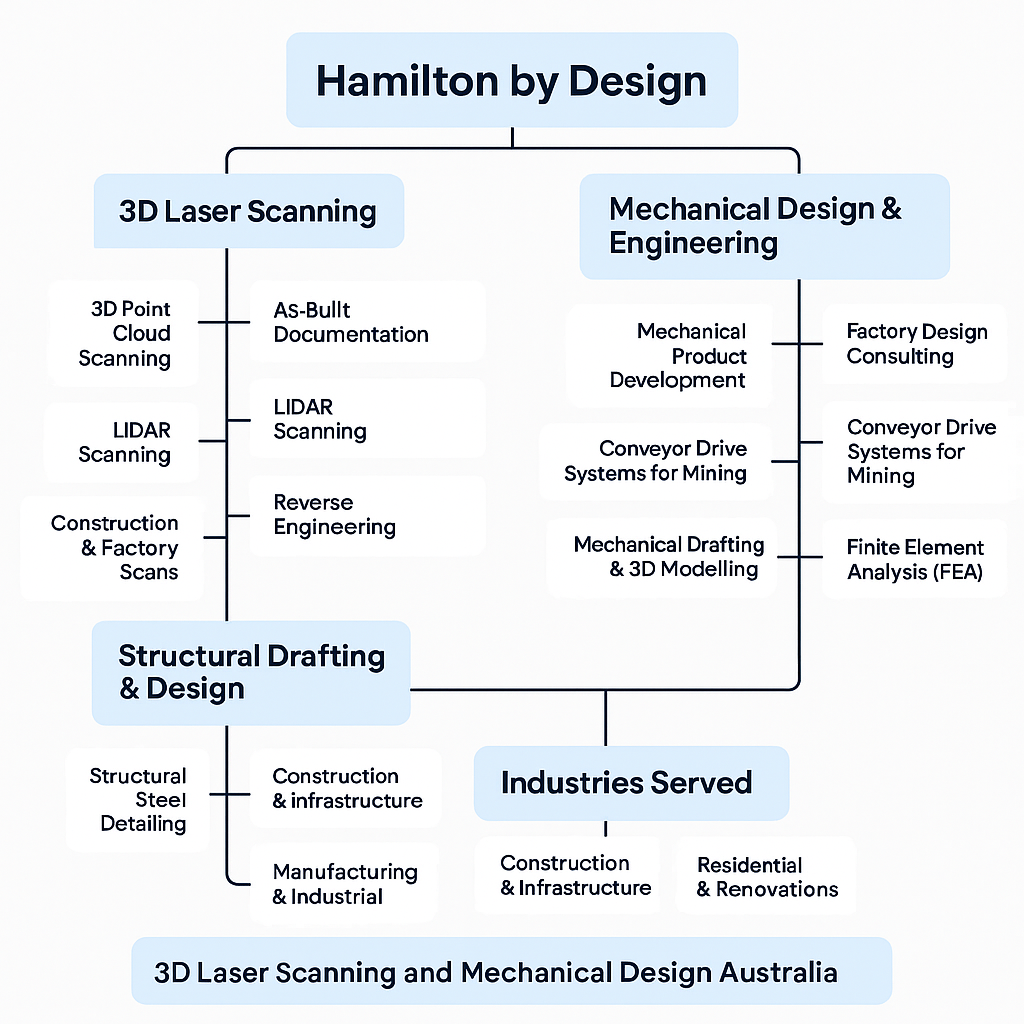

The mining industry, particularly in resource-rich countries like Australia, is a cornerstone of economic activity and development. However, it faces an array of complex challenges including technological advancements, process optimization, and regulatory compliance. Mechanical engineering consultants play a crucial role in helping mining companies navigate these challenges, leveraging their expertise to enhance efficiency, sustainability, and profitability. This essay explores the various ways in which mechanical engineering consultants contribute to the mining sector by providing specialized knowledge and solutions in technology, process optimization, and regulatory compliance.

Technological Advancements

Equipment Design and Selection

One of the primary contributions of mechanical engineering consultants to the mining industry is in the area of equipment design and selection. Mining operations rely heavily on specialized machinery, from excavators and drilling rigs to conveyor systems and crushers. Consultants possess the technical knowledge to design custom equipment tailored to specific mining environments and operational requirements.

For instance, in deep mining operations, consultants can design robust and durable machinery capable of withstanding extreme conditions such as high pressure and temperature. They can also recommend the most suitable equipment based on factors like ore type, mining method, and production capacity. This ensures that mining companies invest in machinery that maximizes productivity while minimizing operational costs.

Automation and Robotics

The integration of automation and robotics in mining operations is another area where mechanical engineering consultants add significant value. Automation technologies, such as autonomous haul trucks and robotic drilling systems, can greatly enhance efficiency and safety in mining operations. Consultants help mining companies implement these technologies by designing and programming automated systems, selecting appropriate sensors and control units, and ensuring seamless integration with existing operations.

For example, autonomous vehicles can operate continuously without the need for breaks, significantly increasing productivity. Additionally, automation reduces the risk of accidents and injuries by removing human workers from hazardous environments. Consultants also provide training and support to ensure that mine operators can effectively manage and maintain these advanced systems.

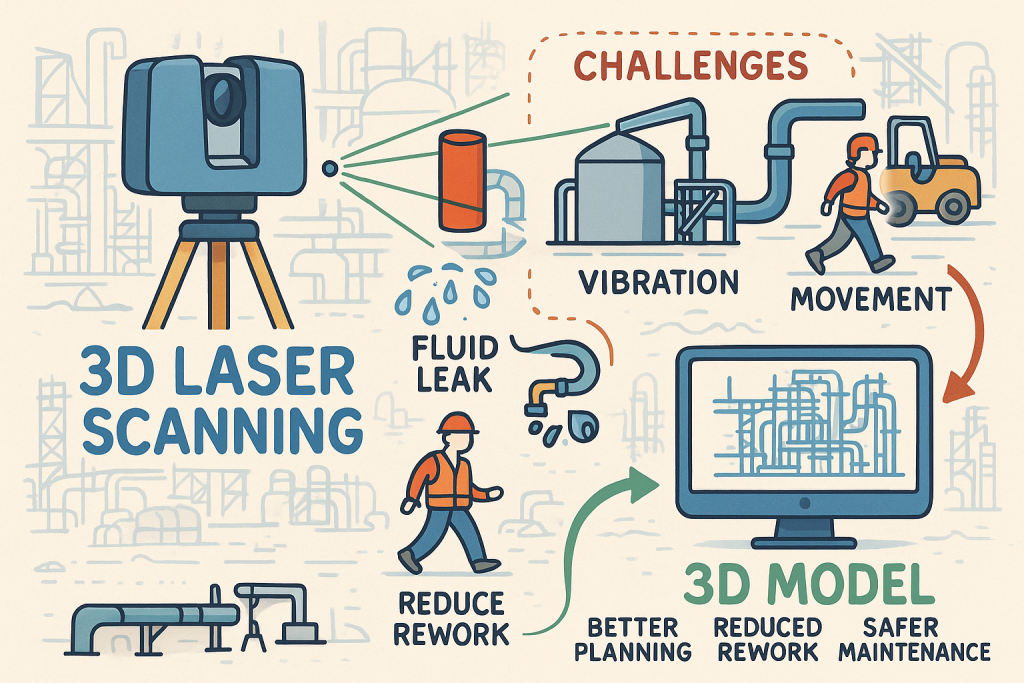

Digitalization and IoT

The adoption of digital technologies and the Internet of Things (IoT) is transforming the mining industry. Mechanical engineering consultants play a pivotal role in this digital transformation by developing and implementing IoT solutions that provide real-time data and analytics. These technologies enable mining companies to monitor equipment performance, track production metrics, and optimize maintenance schedules.

Consultants can design IoT systems that collect data from various sensors installed on mining equipment. This data is then analyzed to identify patterns and predict potential equipment failures before they occur, allowing for proactive maintenance. This approach not only reduces downtime but also extends the lifespan of mining machinery. Furthermore, real-time data analytics enable better decision-making, as managers have access to up-to-date information on all aspects of mining operations.

Process Optimization

Lean Manufacturing Principles

Process optimization is critical for enhancing efficiency and reducing costs in mining operations. Mechanical engineering consultants bring expertise in lean manufacturing principles, which focus on eliminating waste, improving workflow, and maximizing value. By applying these principles, consultants help mining companies streamline their processes and improve overall productivity.

For instance, consultants can conduct value stream mapping to identify bottlenecks and inefficiencies in mining processes. They can then develop strategies to eliminate these bottlenecks, such as reconfiguring workflows, optimizing material handling systems, and improving communication and coordination among different departments. Lean manufacturing techniques also promote continuous improvement, ensuring that mining operations remain efficient and competitive over time.

Energy Efficiency

Energy consumption is a significant cost driver in mining operations. Mechanical engineering consultants can help mining companies improve energy efficiency by conducting energy audits and identifying opportunities for energy savings. This can involve optimizing the operation of energy-intensive equipment, such as grinding mills and pumps, or implementing energy-efficient technologies, such as variable frequency drives and high-efficiency motors.

For example, consultants can recommend the installation of advanced control systems that optimize the operation of grinding mills based on real-time ore characteristics. This ensures that the mills operate at their most efficient point, reducing energy consumption and operating costs. Additionally, consultants can design heat recovery systems that capture and reuse waste heat from mining processes, further enhancing energy efficiency.

Maintenance Optimization

Effective maintenance strategies are essential for ensuring the reliability and longevity of mining equipment. Mechanical engineering consultants can help mining companies develop and implement maintenance optimization programs that maximize equipment availability and minimize downtime. This includes predictive maintenance, which uses data analytics to predict equipment failures before they occur, and preventive maintenance, which involves regularly scheduled maintenance tasks to prevent unexpected breakdowns.

Consultants can design and implement condition monitoring systems that continuously monitor the health of mining equipment. These systems use sensors to collect data on parameters such as vibration, temperature, and pressure, which are then analyzed to detect early signs of wear and tear. By addressing potential issues before they lead to equipment failure, mining companies can avoid costly downtime and extend the lifespan of their machinery.

Regulatory Compliance

Environmental Regulations

Compliance with environmental regulations is a major challenge for mining companies. Mechanical engineering consultants play a crucial role in helping companies meet these requirements by designing and implementing systems that minimize environmental impact. This includes pollution control technologies, waste management systems, and sustainable mining practices.

For example, consultants can design dust control systems that reduce the amount of airborne particulate matter generated by mining operations. These systems can include water sprays, dust suppression chemicals, and ventilation systems that capture and filter dust particles. Consultants can also develop waste management plans that ensure the safe disposal and recycling of mining by-products, such as tailings and slag.

Furthermore, consultants can assist in the design and implementation of sustainable mining practices, such as water conservation and land reclamation. By helping mining companies minimize their environmental footprint, consultants ensure that operations remain compliant with environmental regulations and contribute to sustainable development.

Safety Regulations

Ensuring the safety of workers is paramount in the mining industry, which is subject to strict safety regulations. Mechanical engineering consultants can help mining companies comply with these regulations by designing and implementing safety systems and protocols. This includes the development of risk assessments, safety audits, and emergency response plans.

Consultants can design safety systems that protect workers from hazards such as falling rocks, equipment failures, and exposure to harmful substances. For example, they can design and implement rock fall protection systems, such as mesh nets and rock bolts, that prevent loose rocks from falling in underground mines. They can also develop equipment maintenance protocols that ensure machinery is regularly inspected and maintained to prevent accidents.

In addition to physical safety systems, consultants can provide training and support to ensure that workers are aware of safety protocols and know how to respond in emergency situations. By enhancing safety measures, consultants help mining companies protect their workforce and comply with safety regulations.

Reporting and Documentation

Regulatory compliance requires comprehensive reporting and documentation. Mechanical engineering consultants can assist mining companies in developing and maintaining the necessary records and reports to demonstrate compliance with environmental, safety, and other regulations. This includes the preparation of environmental impact assessments, safety audits, and compliance reports.

Consultants can also implement data management systems that streamline the collection, storage, and retrieval of compliance-related data. These systems ensure that mining companies have access to accurate and up-to-date information needed for regulatory reporting. By managing regulatory documentation, consultants help companies avoid fines and penalties associated with non-compliance.

Case Studies

Automation and Robotics in Mining

One notable example of mechanical engineering consultants aiding mining companies is the implementation of autonomous haul trucks in large mining operations. These trucks, guided by advanced GPS and sensor technologies, operate without human drivers. Mechanical engineering consultants played a pivotal role in designing the automation systems, selecting the appropriate hardware and software, and integrating these technologies with existing mining operations.

The result was a significant increase in productivity and a reduction in operating costs. The autonomous trucks could operate 24/7, without the need for breaks, leading to higher throughput. Additionally, the removal of human drivers from hazardous environments reduced the risk of accidents and injuries, enhancing overall safety.

Energy Efficiency in Grinding Operations

Another case where mechanical engineering consultants made a substantial impact was in improving energy efficiency in grinding operations at a major Australian mining company. Grinding mills are among the most energy-intensive equipment in mining operations. Consultants conducted a comprehensive energy audit and identified opportunities to optimize mill operations.

They recommended the installation of variable frequency drives on the mill motors, which allowed for better control of the grinding process. They also designed an advanced control system that adjusted the mill operation based on real-time ore characteristics. These improvements resulted in a significant reduction in energy consumption, lowering operating costs and reducing the environmental footprint of the mining operation.

Environmental Compliance in Tailings Management

Tailings, the waste materials left after the extraction of valuable minerals, pose significant environmental challenges. A mining company faced regulatory pressure to improve its tailings management practices to prevent environmental contamination. Mechanical engineering consultants were brought in to design a comprehensive tailings management system.

The consultants developed a plan that included the construction of tailings storage facilities with advanced liner systems to prevent leachate contamination. They also designed a water treatment system to treat any water that came into contact with the tailings, ensuring that it met environmental discharge standards. Additionally, the consultants implemented a monitoring system to continuously track the condition of the tailings storage facilities and detect any potential issues.

As a result, the mining company was able to meet regulatory requirements and significantly reduce the environmental impact of its tailings management practices. The comprehensive approach ensured that the company could continue its operations without facing regulatory penalties or damaging its reputation.

Future Trends and Challenges

Advanced Materials and Nanotechnology

As the mining industry continues to evolve, new challenges and opportunities will arise. Advanced materials and nanotechnology are poised to revolutionize mining equipment and processes. Mechanical engineering consultants will play a crucial role in integrating these technologies into mining operations, enhancing efficiency and sustainability.

For instance, nanotechnology can be used to develop stronger and lighter materials for mining equipment, reducing wear and tear and extending the lifespan of machinery. Consultants will need to stay abreast of these technological advancements and provide expertise in selecting and implementing the most promising innovations.

Cybersecurity in Mining

With the increasing reliance on digital technologies and IoT, cybersecurity is becoming a critical concern for the mining industry. Mechanical engineering consultants will need to work closely with cybersecurity experts to ensure that automated and digital systems are protected from cyber threats. This includes designing secure.

To Get in contact with Mechanical Engineering Consultants

Contact Hamilton By Design