Bucket Elevator vs Pan Conveyor Design | Industrial Material Handling Engineering

In bulk material handling industries such as mining, cement production, grain processing, and industrial manufacturing, selecting the right conveying system is critical to reliability, maintenance efficiency, and operating cost. Two commonly used systems are bucket elevators and pan conveyors. While both systems move bulk material efficiently, they are designed for very different operating conditions and material characteristics.

Understanding the difference between the two systems helps engineers select the correct solution for the application.

What is a Bucket Elevator?

A bucket elevator is a vertical conveying system designed to lift bulk materials using a series of buckets attached to either a belt or chain. The buckets scoop material from the boot section and carry it upward to the discharge point.

Bucket elevators are widely used where material must be lifted vertically in a compact footprint.

Key Components

Buckets (steel, nylon, or HDPE)

Belt or chain drive

Boot section (material inlet)

Head section with drive and discharge

Casing or elevator trunking

Typical Applications

Grain handling

Fertiliser plants

Cement and lime processing

Mining concentrate handling

Sand, ash, or powder transport

Advantages

Efficient vertical lifting

Small plant footprint

High throughput capacity

Energy efficient for vertical transport

Limitations

Not ideal for very abrasive or large lump materials

Sensitive to overloading and blockages

Requires careful alignment and maintenance

What is a Pan Conveyor?

A pan conveyor, often called an apron conveyor, transports material horizontally or on shallow inclines using overlapping steel pans attached to heavy-duty chains.

The pans form a continuous moving surface that carries material along the conveyor frame.

Pan conveyors are commonly used in harsh industrial environments where materials are heavy, hot, or abrasive.

Key Components

Steel pans or plates

Heavy-duty conveyor chains

Sprockets and drive system

Conveyor frame

Impact loading zone

Typical Applications

Clinker transport in cement plants

Mining ore handling

Hot ash handling

Crusher discharge conveyors

Furnace feed systems

Advantages

Handles very heavy and abrasive materials

Suitable for impact loading

Reliable in harsh environments

Can operate at slow controlled speeds

Limitations

Larger footprint

Higher capital cost

More power consumption than bucket elevators

Key Differences Between Bucket Elevators and Pan Conveyors

Bucket Elevator

Vertical conveying system

Best for fine to medium bulk materials

Compact footprint

High energy efficiency for vertical transport

Requires controlled loading

Pan Conveyor

Horizontal or inclined conveying system

Handles heavy, abrasive or hot materials

Larger footprint

More robust construction

Handles high impact loading

When to Choose a Bucket Elevator

A bucket elevator is typically the preferred solution when:

Material must be lifted vertically

Plant space is limited

The material is free-flowing

Throughput is high but impact loading is low

Examples include grain silos, cement plants, fertiliser plants, and powder handling systems.

In these situations, bucket elevators provide a compact and energy-efficient solution.

When to Choose a Pan Conveyor

A pan conveyor is the better choice when:

Material is coarse, hot, or abrasive

There is high impact loading

The conveyor must operate continuously in harsh conditions

Reliability is more important than plant footprint

Examples include crusher discharge conveyors, furnace feed systems, clinker transport, and mining ore handling.

Pan conveyors are designed to survive the harshest bulk material handling environments.

Engineering Design Considerations

When designing either system, engineers must consider the following:

Bulk material characteristics

Lump size distribution

Abrasiveness

Moisture content

Throughput requirements

Loading conditions

Maintenance access

Structural support

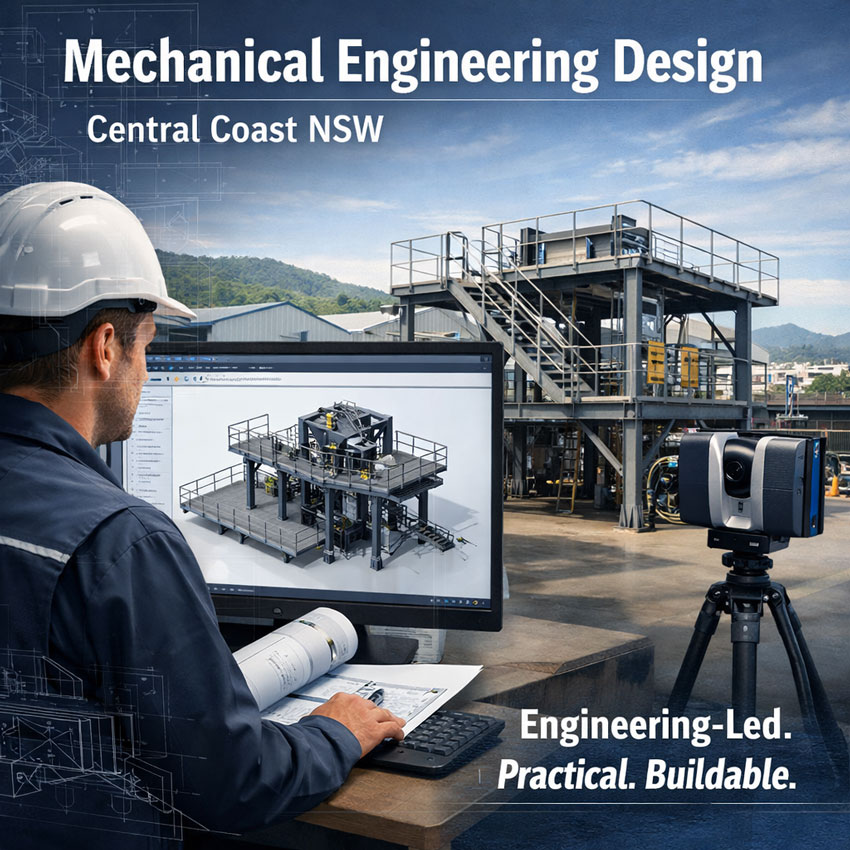

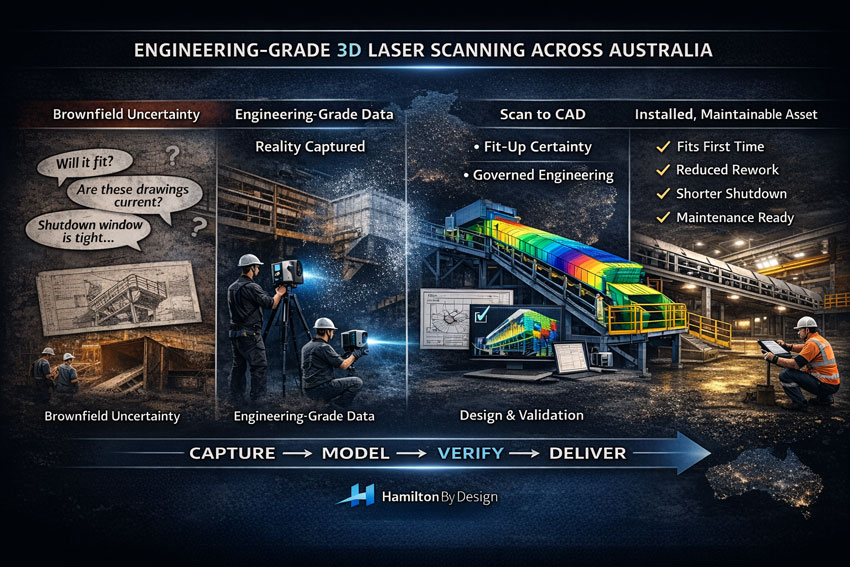

Modern projects often integrate 3D laser scanning and point cloud modelling to ensure conveyors fit within existing plants and connect correctly to existing infrastructure. This approach reduces installation risk and helps engineers verify clearances, structural loads, and maintenance access before fabrication.

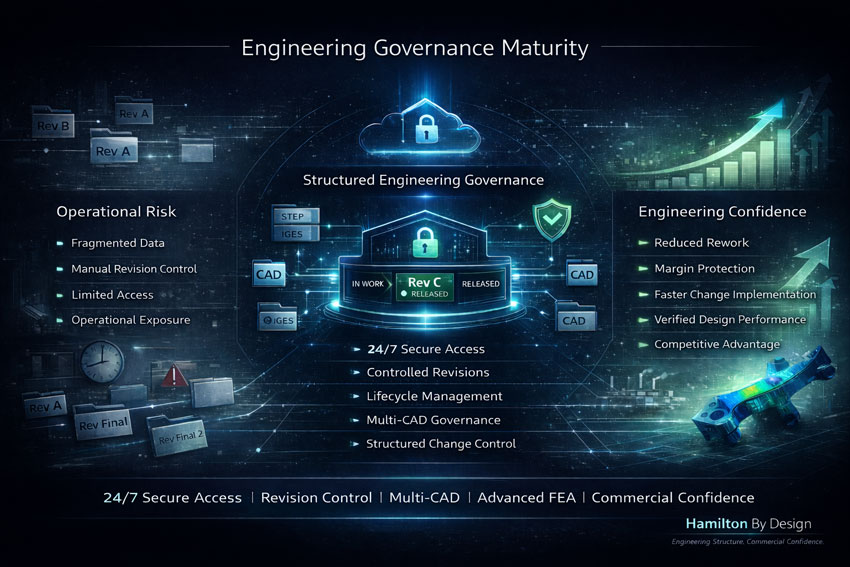

Engineering Support for Conveyor Design

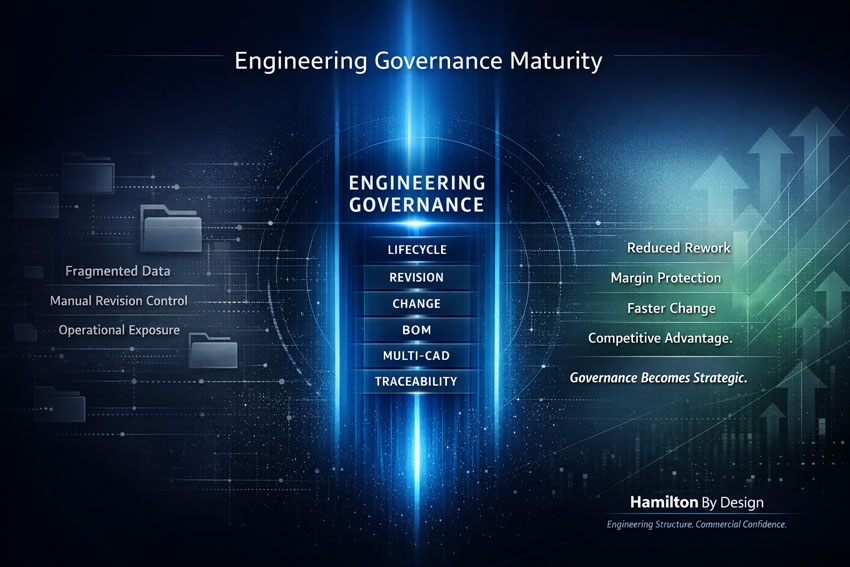

Hamilton By Design supports industrial projects with:

Mechanical conveyor design

3D laser scanning of existing plants

Conveyor chute and transfer design

Structural steel and support frames

Inspection and maintenance optimisation

Whether designing a bucket elevator for vertical material handling or a heavy-duty pan conveyor for mining operations, selecting the correct system is critical to long-term reliability and operational efficiency.