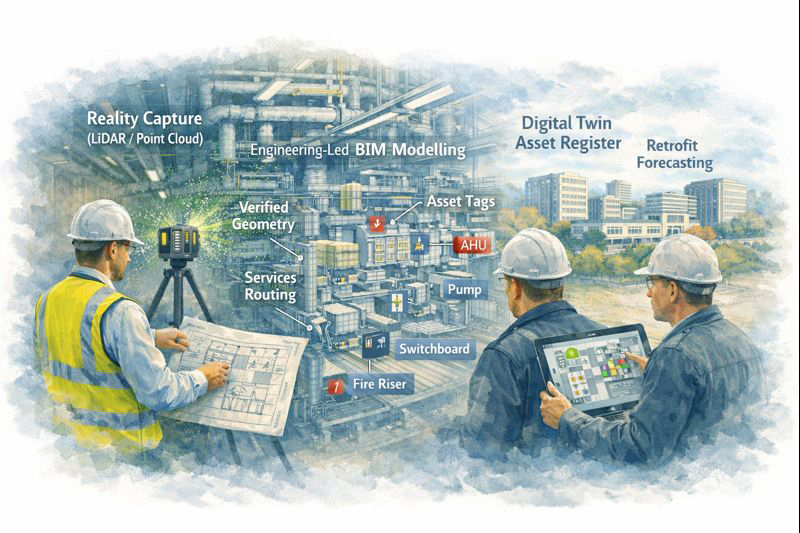

Engineering-Led 3D Laser Scanning for Industrial Facilities in Sydney

In complex industrial environments, accurate site data is critical — but point clouds alone do not solve engineering problems.

At Hamilton By Design, we provide engineering-led 3D laser scanning services across Sydney’s industrial precincts, delivering not just accurate capture, but build-ready CAD models, verified layouts, and engineering support for plant upgrades, shutdown works, and fabrication projects.

From manufacturing facilities and bulk materials handling plants to port infrastructure and brownfield industrial sites, our scanning workflows are designed to reduce rework, improve constructability, and support safe, compliant engineering outcomes.

Why Engineering-Led Scanning Matters in Industrial Environments

Industrial facilities are rarely documented accurately. Over years of modifications, shutdown changes, and emergency repairs, original drawings quickly become unreliable.

Common issues we see on Sydney industrial sites include:

- undocumented structural changes

- misaligned conveyors and transfer points

- access platforms not matching compliance drawings

- equipment upgrades that don’t fit as expected

- safety risks during shutdown installation

Traditional survey-only scanning provides geometry — but without engineering interpretation, design risk remains high.

Hamilton By Design integrates engineering verification directly into the scanning and modelling workflow, ensuring captured data supports:

- mechanical design

- structural verification

- fabrication detailing

- construction planning

This approach is critical for brownfield upgrades and safety-critical installations.

From Point Cloud to Build-Ready CAD — Not Just Visual Models

Our Sydney scanning projects are delivered as part of a complete scan-to-engineering workflow, including:

- high-accuracy terrestrial LiDAR scanning

- registered point cloud datasets

- engineering-grade CAD and BIM modelling

- mechanical and structural integration

- fabrication and construction-ready outputs

This allows project teams to move directly from:

Site capture → engineering design → fabrication → installation

without the delays and risks associated with re-measuring or redesigning due to site conflicts.

For shutdown and live-plant environments, this dramatically reduces:

- installation clashes

- hot-work exposure

- crane and access planning errors

- schedule overruns

Industrial Facilities We Support Across Sydney

Hamilton By Design provides industrial scanning and engineering support across:

- manufacturing plants

- materials handling facilities

- recycling and processing plants

- port and logistics infrastructure

- food and beverage production

- utilities and treatment facilities

Our team understands the constraints of:

- live plant operations

- confined access

- safety compliance requirements

- short shutdown windows

Scanning is planned to integrate with plant operations and maintenance teams, not disrupt them.

Sydney Industrial Precincts We Regularly Support

We provide 3D laser scanning and engineering modelling across key industrial areas including:

- Alexandria and Inner South industrial zones

- Port Botany and logistics precincts

- Western Sydney manufacturing corridors

- North Shore infrastructure and access-restricted sites

- Regional NSW industrial and mining-linked facilities

Each location presents different engineering challenges — from heavy materials handling to structural access compliance — which is why engineering involvement during scanning is critical.

Supporting Engineering, Fabrication and Compliance

Unlike scanning companies that deliver only spatial data, Hamilton By Design integrates scanning into broader project delivery, supporting:

- mechanical upgrades and replacements

- structural strengthening and access platforms

- conveyor and chute modifications

- guardrail and walkway compliance upgrades

- fabrication shop detailing

- as-built documentation for asset registers

This ensures scanning outputs are aligned with:

- Australian Standards

- engineering design requirements

- construction tolerances

Not just visual representation.

Why Industrial Clients Choose Hamilton By Design

Industrial clients across Sydney engage Hamilton By Design because we offer:

- ✔ engineer-led scanning and modelling workflows

- ✔ mechanical and structural design capability in-house

- ✔ fabrication-aware CAD modelling

- ✔ experience in mining and heavy industry environments

- ✔ practical understanding of shutdown and brownfield projects

This allows us to support projects from initial site verification through to construction and commissioning.

When to Use Engineering-Led 3D Scanning

Our Sydney industrial scanning services are particularly valuable for:

- brownfield plant upgrades

- conveyor and materials handling modifications

- access and safety compliance projects

- clash detection before fabrication

- replacement of undocumented equipment

- retrofit installations in congested areas

If the project requires accurate geometry and engineering accountability, scanning must be part of the engineering workflow — not separate from it.

Talk to an Engineering-Led Scanning Team in Sydney

If you are planning an industrial upgrade, shutdown modification, or facility redevelopment in Sydney, Hamilton By Design can provide:

- engineering-led LiDAR scanning

- point cloud to CAD modelling

- mechanical and structural design support

- fabrication-ready documentation

Contact our team to discuss how engineering-driven site capture can reduce project risk and improve construction outcomes.