Discover how mechanical engineering, government funding, and digital innovation are driving the future of mining in Australia. Learn how Hamilton By Design leads the change.

Australia’s mining industry is undergoing one of its most significant transformations in decades. At the heart of this change lies the convergence of mechanical engineering innovation, government-backed funding, and cutting-edge technology.

With over $750 million in federal support for metals manufacturing and state-based funding for METS innovation, mechanical engineers are now in a position to redefine how mining operations are designed, maintained, and optimised.

At Hamilton By Design, we are helping clients across the country harness these changes—offering smart mechanical solutions that are efficient, resilient, and future-ready.

Key Opportunities: How Technology is Reshaping Mechanical Engineering in Mining

1. Government Funding is Fueling Innovation

In March 2025, the Australian Government announced a $750 million investment to boost advanced manufacturing and metals production in Australia.

🔗 Backing Our Metals Manufacturers – Federal Government

This funding opens doors for:

-

Prototyping new mechanical assemblies

-

Automation upgrades for existing mining plants

-

Local manufacturing partnerships to reduce supply chain risk

At Hamilton By Design, we are already supporting mining clients to align their capital projects with these funding pathways.

2. Digital Tools Enhance Mechanical Performance

According to the CSIRO METS Roadmap, digitalisation and automation are critical for the next phase of mining growth.

We implement:

-

LiDAR scanning for as-built plant modelling

-

Finite Element Analysis (FEA) for structural design optimisation

-

Predictive maintenance planning using real-time sensor data

These tools not only extend the life of critical components but also enhance safety, reduce downtime, and support remote operations.

3. WA and NSW Governments Are Supporting METS Innovation

The Western Australian government continues to support Mining Equipment, Technology and Services (METS) innovation and commercialisation through its METS Innovation Grants.

This creates opportunities for mechanical engineering firms to:

-

Collaborate with OEMs and fabricators

-

Introduce novel materials and designs for harsh mining environments

-

Lead the push toward zero-emissions equipment and sustainable design

Hamilton By Design’s agile project delivery and deep mechanical experience allow us to integrate seamlessly with these innovation pipelines.

The Challenges: Bridging the Gap Between Legacy and Future

Despite the exciting momentum, the sector also faces critical challenges:

-

Skills Gaps: Many engineers are not yet equipped with digital or automation skills.

-

System Complexity: Mechanical systems are increasingly integrated with electrical and digital subsystems, requiring multidisciplinary design thinking.

-

Capital Risk: Large investments in automation must deliver measurable value, which requires robust mechanical frameworks.

Hamilton By Design addresses these risks by offering not only high-quality design services, but also strategy, planning, and training support to ensure seamless project delivery.

Why Hamilton By Design is Your Engineering Partner of the Future

We don’t just design parts—we engineer solutions.

Our core services include:

-

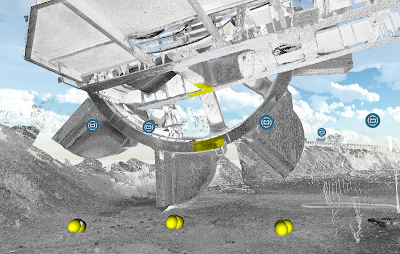

Mining mechanical design (transfer chutes, diverter systems, sheet metal)

-

Structural and stress analysis (using FEA and vibration simulation)

-

LiDAR-enabled plant scanning for reverse engineering and documentation

-

Sustainable, future-ready mechanical engineering consultancy

We work with clients across NSW, WA, QLD, and SA, offering nationwide support for design, development, and delivery.

Let’s Engineer the Future Together

Mechanical engineering is no longer just about function—it’s about intelligence, adaptability, and sustainability.

At Hamilton By Design, we help mining companies, fabricators, and OEMs thrive in this new landscape. Whether you’re applying for funding, upgrading equipment, or redesigning your processing infrastructure, we have the tools, experience, and innovation to lead you forward.

Contact us at

Email – info@hamiltonbydesign.com.au

Phone – (+61) 0477 002 249

Our clients:

Hamilton By Design | Mechanical Drafting | Structural Drafting | 3-D Lidar Scanning